Automatic mixer has the following characteristics and advantages:1. Efficient mixing: The automatic mixer can efficiently mix different materials to achieve uniform distribution and consistency, and improve production efficiency and product quality.2. Reduce manual intervention: Compared with manual mixing, automatic mixing machine can reduce manual operation and intervention, improve work efficiency, and reduce the risk of human operation error.3.

Contact Now

Auto ceiling accessories automatic assembly equipment:1. Improve production efficiency: Auto ceiling accessories automatic assembly equipment can quickly and accurately complete the assembly of car roofs, thereby improving production efficiency.2. Reduce labor costs: Compared with manual assembly, auto ceiling accessories automatic assembly equipment can reduce manual participation and reduce labor costs.3. Improve product quality: Automatic assembly equipment can ensure the consistency and accuracy of assembly, thereby improving product quality.4.

Contact Now

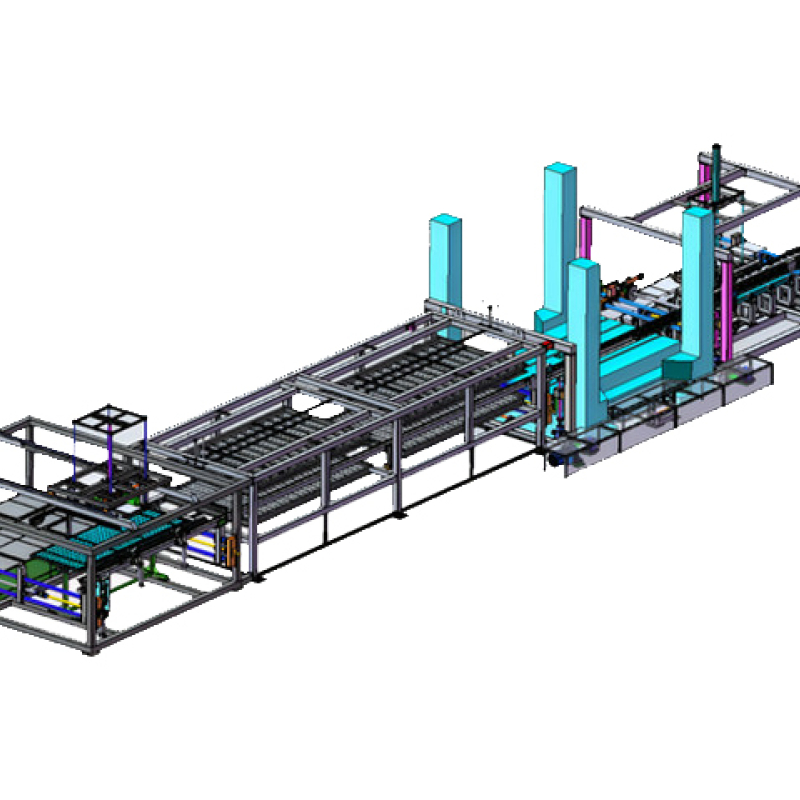

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Automotive ceiling automatic PU board equipment has many advantages:1. Automatic operation: The equipment adopts automatic technology, which can realize the automatic positioning, pasting and pressing of PU sheet without too much manual operation. This greatly increases productivity and reduces the risk of human error.2. Accurate paste position: The equipment is equipped with an accurate positioning system, which can accurately locate the position of the car ceiling to ensure the accuracy of PU sheet paste.

Contact Now

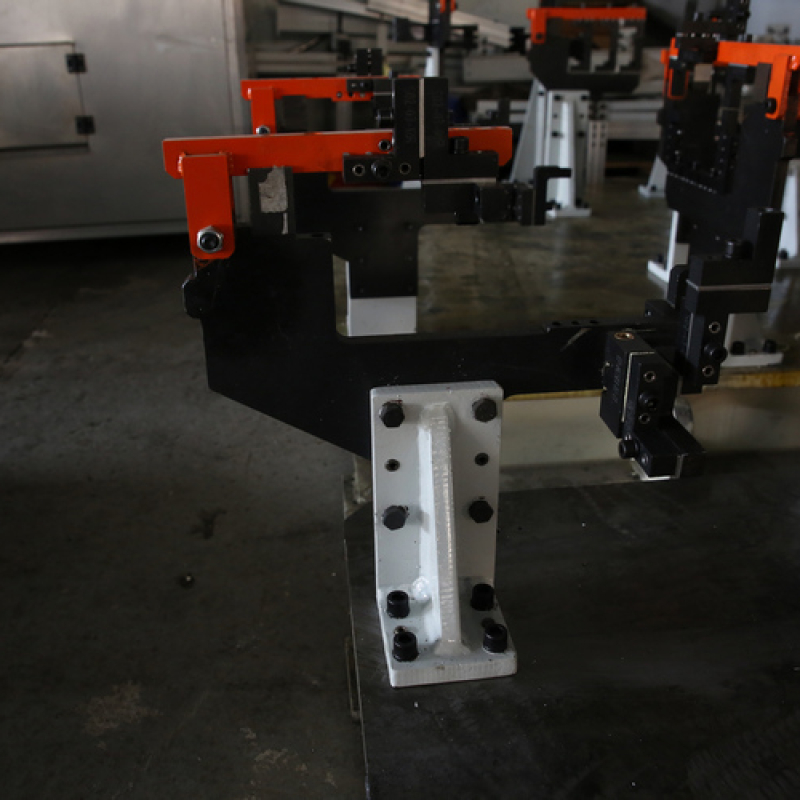

Skylight visor automatic edge wrapping equipment is a kind of equipment used for processing automotive sunroof visor, with the following advantages:1. Efficient automation: The skylight visor automatic wrapping equipment adopts automation technology, which can achieve fast and accurate processing. Through the automated operation process, the production efficiency can be greatly improved and the labor cost can be reduced.2.

Contact Now

Multi layer slicing automatic composite feeding machine has the following advantages:1. High efficiency: The equipment can realize automatic slicing and compounding process, which greatly improves production efficiency and work efficiency. Compared to manual operation, automated equipment can complete tasks faster and can continue to operate without operator fatigue or rest.2. Accuracy: The multi layer slicing automatic composite feeding machine adopts advanced control and positioning technology, which can achieve high-precision cutting and composite.

Contact Now

Auto trunk cover plate automatic edge wrapping equipment has the following advantages:1. Improve production efficiency: Auto trunk cover plate automatic edge wrapping equipment can greatly improve production efficiency. Compared to manual assembly, automated systems can complete each step of roof assembly quickly and accurately.

Contact Now

Automatic slicing compound feeding machine has the following advantages:1. High efficiency: The machine can automatically slice, compound and feed operations, greatly improving the production efficiency.2. Precision: The machine can precisely control the cutting and compounding of materials, thus ensuring the quality and stability of the product.3. Automation: The machine can automatically complete multiple processes, reducing manual operation and reducing production costs.4.

Contact Now

Car roof dry automatic molding line mainly includes: substrate loader, conveying system (including girder lifting and width adjustment system), two-stage heating and drying furnace, auxiliary material table, mold centering device, mold changing car, printer table, work Steps and safety protection devices, etc.skills requirement:1. The largest substrate and fabric size: 2950×1800mm.2. The production cycle meets the requirement of 45-60 seconds/piece.3. The horizontal height of substrate transmission: 1320mm.4.

Contact Now

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.3.

Contact Now

The main parameters of car roof multi-layer automatic slicing compound feeding machine:1. A-B fiberglass pulling and rubber roller feeding adopt servo motor plus synchronous belt mechanism; station movement and stacking table transmission mechanism adopt motor plus frequency converter plus synchronous belt mechanism.2. The lifting and traversing trolley of the PU board is controlled by a frequency conversion motor, and the rotation is controlled by a servo motor.3. Product size range: the maximum product size is 2500*1500mm, and the minimum product size is 1200*860mm.4.

Contact Now

Characteristics of the bulk powder handling equipment:1. Integrated grinding and classifying machine.2. Compact, space-saving design.3. Stable and narrow particle size distribution and simple adjustment.4. Cutting accuracy is easy to adjust.5. High availability and automation levels.6. Automatic pneumatic feeding system saves time and effort.7. low noise emission.8. Low specific energy consumption.9. Wear protection.10. Environmentally friendly design to minimize ultrafine emissions.11. Easy to clean and maintain.

Contact Now

The sheet forming machine has the following advantages:1. With the function of automatic rotation and tablet pressing, it enters the hopper through the closed barrel and the closed conveying system, and takes effective measures to prevent dust flying and particle stratification during the tablet pressing process. The pressed tablet enters the packaging process through the screen, chip detection, metal detection, etc. The whole process is quite closed.2. The sheet forming machine has a start, end and speed adjustment function.

Contact Now

HLJ type powder blending equipment is highly regarded for its excellent mixing performance and wide range of applications. As the first key equipment in the electrostatic powder coating production line, it undertakes the important task of mixing various materials evenly. Whether it is HLJ300, HLJ500 or HLJ800, each model has its unique features and advantages to meet the different scale and production requirements of the coating line.Model HLJ300 is suitable for small to medium sized production lines.

Contact Now

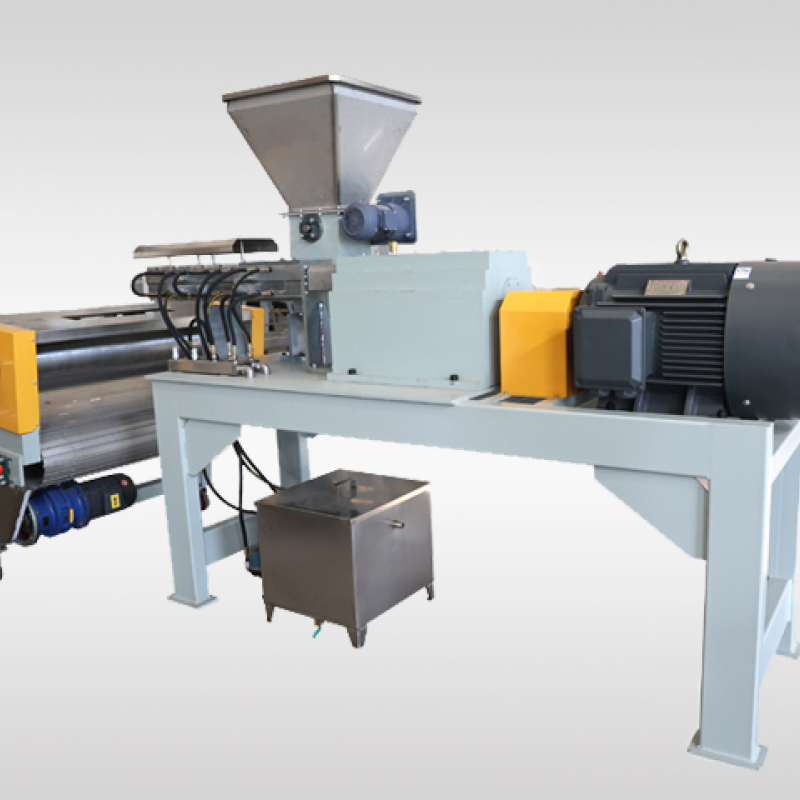

Extruder machine is a widely used equipment in industrial production, especially in the processing of plastics, rubber and other materials play an indispensable role. This extruder adopts the design of single-screw upper feeding, which not only improves the feeding efficiency, but also ensures the uniformity of feeding.

Contact Now

Single screw reciprocating extruder has the following advantages:1. Efficient production: single screw reciprocating extruder adopts reciprocating motion design, through the reciprocating extrusion action, can achieve high-speed and efficient production of plastic products. Compared to traditional single-screw extruders, reciprocating extruders can produce more product in the same amount of time.2. Energy saving: The design of the single-screw reciprocating extruder makes the use of energy more efficient.

Contact Now

SLJ twin screw extruder has the following advantages:1. High production efficiency: SLJ twin screw extruder adopts twin screw structure, with greater extrusion capacity and higher extrusion speed. Compared with a single screw extruder, it can produce more plastic products in the same time, improving production efficiency.2. Good mixing performance: The twin screw extruder can better mix plastic raw materials through two mutually integrated rotating screws. This ensures the uniform distribution and full integration of raw materials and improves the quality of finished products.3.

Contact Now

Product Details Of Powder Coating Extruder JCJ63: Earlier than the extruder begins to paintings each time, turn the motor with the crank handle to see if the rotation is straightforward and exertions-saving. In any other case, it ought to be stored on the manner temperature for 3 to 5 minutes, till the rotation is exertions-saving, and then it's far allowed to start operation.Each time the extruder starts offevolved to paintings, the screw runs at a low speed and feeds a touch.

Contact Now

Product Details Of Powder Coating Extruder JCJ30:Before the extruder starts offevolved to work every time, flip the motor with the crank manage to see if the rotation is effortless and labor-saving. Otherwise, it need to be saved at the method temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder begins to work, the screw runs at a low velocity and feeds a little.

Contact Now

Product Details Of Powder Coating Extruder JCJ75: Before the extruder starts offevolved to work every time, flip the motor with the crank cope with to see if the rotation is handy and labor-saving. Otherwise, it ought to be saved at the procedure temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder starts offevolved to work, the screw runs at a low velocity and feeds a little.

Contact Now

Technical characteristics of this powder coating extruder:The powder coating extruder, as a high-precision mechanical equipment, occupies a pivotal position in the material processing industry. Its technical characteristics are not only reflected in efficient processing capabilities, but also demonstrate its excellent performance in details.Before each start, the machine performs a pre-rotation check on the motor through the turning crank. This step may seem simple, but it greatly improves the stability and safety of the equipment.

Contact Now

Extruder machine for powder coating is a device used to produce or process powder coating. It is commonly used to manufacture powder coatings, but can also be used to modify or reprocess existing powder coatings. The following is the general working principle and main characteristics of the extruder:First.

Contact Now

Product advantages:1. in terms of strength, the traditional iron workbench looks very strong on the surface, but the main connection is by welding joints. Once it is under heavy pressure, the solder joints fall off and the whole body will collapse. However, the aluminum profile workbench adopts a connection and locking structure. , Even if the force is too large, it can return to its position.2. in terms of maintenance, if a single connection part of a traditional iron workbench is damaged, it needs to be re-welded, polished, painted, etc.

Contact Now