The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Toyota Eifang RAV4 line speed transmission line has the following advantages:1. Improve production efficiency: The line speed transmission line uses an automated way to transmit the vehicle or vehicle parts from one workstation to another in an uninterrupted state, reducing the pause time in the production process and improving production efficiency.2. Quality control: Through the use of line speed transmission lines, Toyota can achieve strict control over the production process to ensure that each vehicle is assembled and inspected in accordance with standard procedures.

Contact Now

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

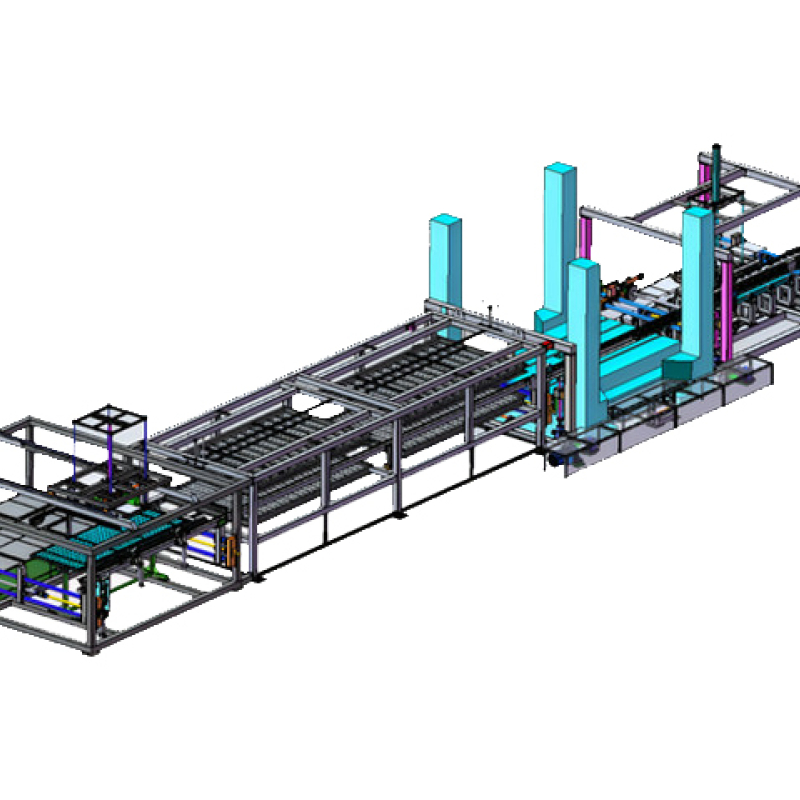

Car roof dry automatic molding line mainly includes: substrate loader, conveying system (including girder lifting and width adjustment system), two-stage heating and drying furnace, auxiliary material table, mold centering device, mold changing car, printer table, work Steps and safety protection devices, etc.skills requirement:1. The largest substrate and fabric size: 2950×1800mm.2. The production cycle meets the requirement of 45-60 seconds/piece.3. The horizontal height of substrate transmission: 1320mm.4.

Contact Now

Automated processing has several advantages:1. High precision: During the machining process, through precise machine tool and cutting tool control, high-precision machining can be achieved to meet strict requirements for size, shape and surface quality. The stability of the machine tool and the high-precision motion system ensure the accuracy and repeatability of the workpiece.2. Diversity: Automated processing is suitable for a variety of materials, including metals, plastics, ceramics, and more.

Contact Now

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.3.

Contact Now

The Cadillac XT5 Line has the following advantages:1. Improve production efficiency: The use of automation technology can achieve continuous and efficient vehicle or parts transmission, reducing the pause time in the production process and improving production efficiency. This helps speed up production and increase output.2. Quality control: The use of wire speed transmission line can achieve strict control of the production process. Each vehicle is inspected and tested as it passes through the various workstations to ensure accurate quality standards are met.

Contact Now

Auto trunk cover plate automatic edge wrapping equipment has the following advantages:1. Improve production efficiency: Auto trunk cover plate automatic edge wrapping equipment can greatly improve production efficiency. Compared to manual assembly, automated systems can complete each step of roof assembly quickly and accurately.

Contact Now

The automobile wiring harness high-altitude spreader station conveying device is located in the upper space of the operation workbench, making full use of the space advantages of the site and avoiding site waste. High degree of intelligence, can automatically and quickly realize the loading and unloading of products between the two stations and process buffering, and will not be affected by the inconsistency of the production rhythm between the on-site production stations.

Contact Now

Features:1.High welding precision and steadiness of spare parts.The jigs welding fixtures are used for constant spare parts. It ensures the right relative function at some point of the manufacturing process. Workpeice deformation can be prevented. Especially in mass production, the fixtures warranty exceptional welding quality.2.High welding precision of the widely wide-spread automobile body, handy operation.Spare components of clamping mechanism makes use of materials of equal mechanical performance.

Contact Now

Advantages of sheet metal production:1. The number of stamping operations is simple and convenient, and has advantages for workpieces with complex shapes, but the thickness should be within the machinable range. After the program programming is completed, the circuit board can be processed automatically. In addition to the need to invest certain costs in the early stages, low investment costs in the later stages can help companies improve economic benefits.2. The quality of the finished product.

Contact Now

HLJ type powder blending equipment is highly regarded for its excellent mixing performance and wide range of applications. As the first key equipment in the electrostatic powder coating production line, it undertakes the important task of mixing various materials evenly. Whether it is HLJ300, HLJ500 or HLJ800, each model has its unique features and advantages to meet the different scale and production requirements of the coating line.Model HLJ300 is suitable for small to medium sized production lines.

Contact Now

In the electrostatic powder coating production line,powder mixer blender is undoubtedly the equipment that plays a vital role. With its unique advantages, it brings a lot of convenience and benefits to the whole production process.First of all, the powder mixer blender, with its efficient mixing performance, ensures that a variety of materials can be evenly mixed in a short period of time. This makes it possible to precisely control the proportion of the coating components, thus substantially improving the quality of the coating.

Contact Now

Fix wiring harness fixtures have the following advantages:1. Improve production efficiency: Wire harness fixtures can automatically test and verify wire harnesses, reducing the time and effort required for manual operations. It can quickly connect and disconnect wire harnesses, effectively improving the efficiency of the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure that each wire harness is tested and verified according to the same standards, thus ensuring consistency and quality control.

Contact Now

The main parameters of car roof multi-layer automatic slicing compound feeding machine:1. A-B fiberglass pulling and rubber roller feeding adopt servo motor plus synchronous belt mechanism; station movement and stacking table transmission mechanism adopt motor plus frequency converter plus synchronous belt mechanism.2. The lifting and traversing trolley of the PU board is controlled by a frequency conversion motor, and the rotation is controlled by a servo motor.3. Product size range: the maximum product size is 2500*1500mm, and the minimum product size is 1200*860mm.4.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Main advantages of drying equipment in factories:1. Consistent product quality: The tablet press can evenly compress powder or granular materials into consistent tablets, granules or other shaped solid products. This ensures consistent quality for each product, eliminating variations that may occur during manual production.2. High production efficiency: The tablet press can perform continuous production at a high speed. They usually have automated control systems that enable efficient raw material feeding, pressing and product discharge, thereby improving production efficiency.3.

Contact Now

Skylight visor automatic edge wrapping equipment is a kind of equipment used for processing automotive sunroof visor, with the following advantages:1. Efficient automation: The skylight visor automatic wrapping equipment adopts automation technology, which can achieve fast and accurate processing. Through the automated operation process, the production efficiency can be greatly improved and the labor cost can be reduced.2.

Contact Now

Multi layer slicing automatic composite feeding machine has the following advantages:1. High efficiency: The equipment can realize automatic slicing and compounding process, which greatly improves production efficiency and work efficiency. Compared to manual operation, automated equipment can complete tasks faster and can continue to operate without operator fatigue or rest.2. Accuracy: The multi layer slicing automatic composite feeding machine adopts advanced control and positioning technology, which can achieve high-precision cutting and composite.

Contact Now

Our advantages:1. Independent design and development, processing and production, no other middlemen, low production cost, excellent product price.2. It can be customized according to the customer's product production needs, and can meet different customer needs.

Contact Now

Performance characteristics of flour millFlour mill occupies a pivotal position in the production of thermosetting electrostatic powder coatings. As the grand finale of the entire production process, it is responsible for the fine grinding of raw materials into high quality coatings. By virtue of its precise grinding ability, the mill can ensure that the fineness and uniformity of the coating product reaches the highest standard, thus meeting the market demand for high-quality coatings.The flour mill's efficient working principle is the key to its excellent performance.

Contact Now

Welding fixture is an auxiliary device wanted in the manner of physique welding. The workpiece can be precisely located on the vehicle manufacturing line thru the welding fixture, and the welding computer can be guided to the role for welding via the fixture. In the system of physique welding, the vehicle physique is made of steel materials, and the fixture is an imperative phase of metallic welding.

Contact Now

The cooling belt offers many advantages, including:1. Uniform cooling: The cooling belt is designed to provide a uniform cooling process, ensuring that the product maintains a consistent temperature throughout the production process.2. Energy saving and high efficiency: Compared with traditional cooling methods, air cooling belts can achieve energy-saving and efficient cooling effects by using air flow more effectively.3.

Contact Now

Using cooling belt in factories has the following advantages:1. Improve production efficiency: The cooling belt can automatically complete the product pressing process, greatly improving production efficiency.2. Reduce production costs: By using a cooling belt, manual operations and scrap rates can be reduced, thereby reducing production costs.3. Stable product quality: The cooling belt can adjust the pressure and mold shape as needed to produce products that meet specifications and quality requirements.4.

Contact Now