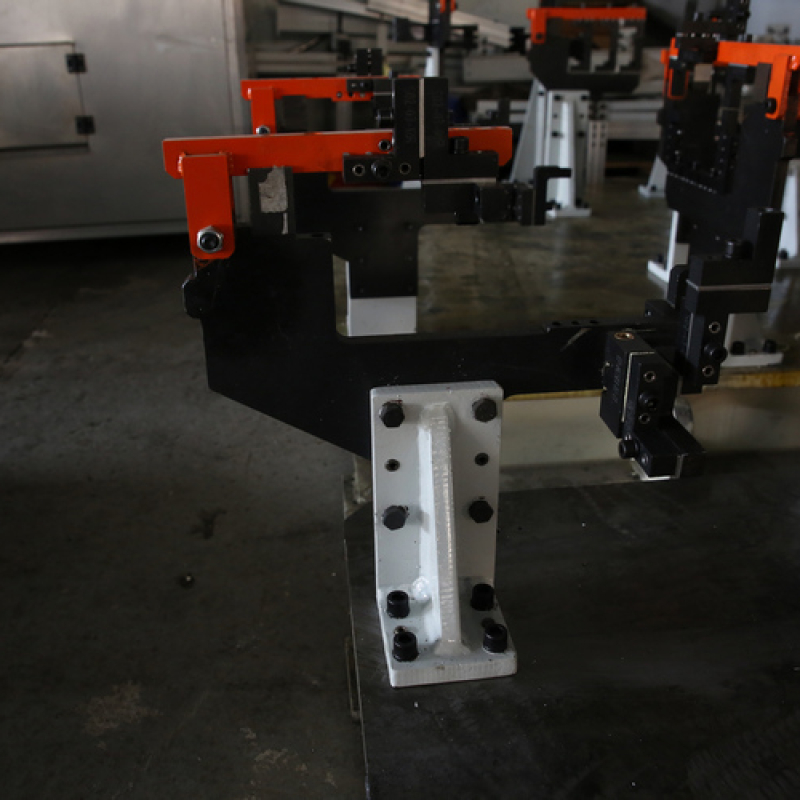

Welding fixture is an auxiliary device wanted in the manner of physique welding. The workpiece can be precisely located on the vehicle manufacturing line thru the welding fixture, and the welding computer can be guided to the role for welding via the fixture. In the system of physique welding, the vehicle physique is made of steel materials, and the fixture is an imperative phase of metallic welding.

Contact Now

1. Composition of auto body-in-white welding fixture.Welding fixture is an auxiliary means in the production of products. It is a general term for the process equipment used for assembly and welding, including the guiding device for guiding the welding torch or the workpiece, which quickly and accurately locates and fixes the workpiece at the desired position. Welding fixture is an indispensable auxiliary device for metal structure welding and an important part of the welding process.

Contact Now

Features:1.High welding precision and steadiness of spare parts.The jigs welding fixtures are used for constant spare parts. It ensures the right relative function at some point of the manufacturing process. Workpeice deformation can be prevented. Especially in mass production, the fixtures warranty exceptional welding quality.2.High welding precision of the widely wide-spread automobile body, handy operation.Spare components of clamping mechanism makes use of materials of equal mechanical performance.

Contact Now

Automotive assembly fixtures play an important role in the manufacturing and production process. Their main functions include:1. Positioning and clamping: The workpiece fixture can fix and clamp the workpiece to maintain its correct position and attitude. They provide accurate positioning, ensuring the exact location of workpieces during machining, assembly and other operations.2. Increased productivity: By using fixtures, operators can complete machining, assembly and other production tasks more quickly and accurately.

Contact Now

The following are the advantages of the wiring harness fixture:1. Easy to use: wiring harness fixture can be quickly and easily installed and adjusted without any professional tools. Simply place the wires and cables into clamps and then clamp them manually or automatically.2. Flexibility: wiring harness fixture has a high degree of flexibility, suitable for a variety of different types of wire and cable. The clamps can be adjusted or moved as needed to suit different applications and wiring needs.3.

Contact Now

Fixtures have been extensively used earlier than the industrial age, inclusive of mechanical fixtures, woodworking fixtures, welding fixtures, rings fixtures, and different fields.

Contact Now

The predominant characteristic of the tooling hole fixture is to restore and hit upon the function of the object. Compared with the jig, it has an extra positioning function. The jigs that are frequently considered will use geometric restrictions to role the object, so like positioning blocks, positioning Pins regularly have a bevel format to guide the object into a fantastically small area and restriction the function of the object.

Contact Now

Auto parts tooling fixtures have the following advantages:1. High positioning accuracy: Auto parts tooling fixtures can provide accurate positioning and clamping to ensure the correct position and attitude of auto parts during processing and assembly. This ensures precision and consistency in part assembly, improving overall product quality.2. Improved productivity: By using automotive parts fixtures, operators can complete assembly and machining tasks faster and more accurately.

Contact Now

Sheet metal products have the following advantages:1. Lightweight design: Since sheet metal products are usually made of metal sheets, they are lighter than traditional solid parts. This helps reduce overall product weight, improving portability and ease of installation. It is especially important for areas such as automotive, aerospace and electronic equipment that require weight control.2. Excellent structural rigidity: Sheet metal products can form complex structures through bending, welding, etc., and have high rigidity and stability.

Contact Now

Product advantages:1. in terms of strength, the traditional iron workbench looks very strong on the surface, but the main connection is by welding joints. Once it is under heavy pressure, the solder joints fall off and the whole body will collapse. However, the aluminum profile workbench adopts a connection and locking structure. , Even if the force is too large, it can return to its position.2. in terms of maintenance, if a single connection part of a traditional iron workbench is damaged, it needs to be re-welded, polished, painted, etc.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Skylight visor automatic edge wrapping equipment is a kind of equipment used for processing automotive sunroof visor, with the following advantages:1. Efficient automation: The skylight visor automatic wrapping equipment adopts automation technology, which can achieve fast and accurate processing. Through the automated operation process, the production efficiency can be greatly improved and the labor cost can be reduced.2.

Contact Now

Product advantages:Compared with the production and processing of forgings and castings, hand metal bender has the advantages of light weight, saving metal materials, simple processing technology, reducing production costs, and saving production expenses. Most of the hand metal bender that has been welded have low processing accuracy and large welding deformation.

Contact Now

Products advantages:1. Lightweight: Compared with solid metal components, metal pallets are composed of thin plates and therefore have a lighter weight.2. Strength and stiffness: Processing metal plates through bending, welding and other processes can enhance the structural strength and stiffness of the product.3. Beautiful appearance: Metal pallet can be polished, sprayed and other surface treatments to give them a good appearance.4.

Contact Now

Automotive ceiling automatic PU board equipment has many advantages:1. Automatic operation: The equipment adopts automatic technology, which can realize the automatic positioning, pasting and pressing of PU sheet without too much manual operation. This greatly increases productivity and reduces the risk of human error.2. Accurate paste position: The equipment is equipped with an accurate positioning system, which can accurately locate the position of the car ceiling to ensure the accuracy of PU sheet paste.

Contact Now

Product advantages:1. Lightweight:Sheet stamping is typically lighter than traditional metal products, making them more practical in many applications. For example, in the automotive manufacturing industry, the use of sheet metal products can reduce the weight of vehicles, thereby improving fuel effciency and performance.2. Corrosion resistance: Sheet metal products often have a high level of corrosion resistance, which makes them more durable in many applications. 3. Plasticity: Sheet metal products have high plasticity, which allows them to be made into various shapes and sizes.

Contact Now

Product advantages:1. Reduce material waste.Bent sheet metal is the process of bending metal sheets into the desired shape. It can reduce the waste of material in operations such as cutting and welding as much as possible while ensuring the quality of the workpiece. This not only reduces the cost of material procurement, but also shortens the production process and reduces the scrap rate, contributing to environmental protection.2.

Contact Now

Advantages of sheet metal finishing:1. Flexibility: Sheet metal finishing can flexibly customize and manufacture parts and products of various shapes and sizes according to customer needs and design requirements.2. High precision: Advanced sheet metal finishing equipment and technology can achieve high-precision cutting, bending and punching operations to ensure product quality.3. Wide range of materials: Sheet metal finishing can be applied to a variety of metal materials, such as stainless steel, aluminum alloy, carbon steel, etc., to meet the needs of different application fields.4.

Contact Now

Sheet metal processing products have the following advantages:1. High strength: Metal frame are usually made of metal materials, which have high strength and rigidity and can withstand certain loads and pressures.2. High precision: Metal frame are usually processed using CNC processing equipment, which has high processing precision and accuracy and can meet high-precision manufacturing needs.3. Good corrosion resistance: Metal frame are usually made of stainless steel, aluminum alloy and other materials.

Contact Now

Sheet metal panels have the following advantages:1. High shape accuracy: Sheet metal panels can be processed by CNC equipment, which can achieve high-precision shape requirements.2. Wide selection of materials: It can process a variety of metal materials, such as stainless steel, aluminum alloy, copper alloy, etc. Different materials can be selected according to needs.3. Flexible process: Sheet metal panels can use a variety of processes, such as bending, stamping, shearing, etc. Different processes can be selected according to needs.4.

Contact Now

Toyota Eifang RAV4 line speed transmission line has the following advantages:1. Improve production efficiency: The line speed transmission line uses an automated way to transmit the vehicle or vehicle parts from one workstation to another in an uninterrupted state, reducing the pause time in the production process and improving production efficiency.2. Quality control: Through the use of line speed transmission lines, Toyota can achieve strict control over the production process to ensure that each vehicle is assembled and inspected in accordance with standard procedures.

Contact Now

The Cadillac XT5 Line has the following advantages:1. Improve production efficiency: The use of automation technology can achieve continuous and efficient vehicle or parts transmission, reducing the pause time in the production process and improving production efficiency. This helps speed up production and increase output.2. Quality control: The use of wire speed transmission line can achieve strict control of the production process. Each vehicle is inspected and tested as it passes through the various workstations to ensure accurate quality standards are met.

Contact Now

Fix wiring harness fixtures have the following advantages:1. Improve production efficiency: Wire harness fixtures can automatically test and verify wire harnesses, reducing the time and effort required for manual operations. It can quickly connect and disconnect wire harnesses, effectively improving the efficiency of the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure that each wire harness is tested and verified according to the same standards, thus ensuring consistency and quality control.

Contact Now

Advantages of CNC machining:1. High repeatability and precision.2. Volume of manufacturing is very high.3. Complex contours/surfaces want to be machined.etc..4. Flexibility in job change, computerized device settings, much less scrap.5. More safe, greater productivity, higher quality.6. Less paper work, quicker prototype production, reduction in lead instances.

Contact Now