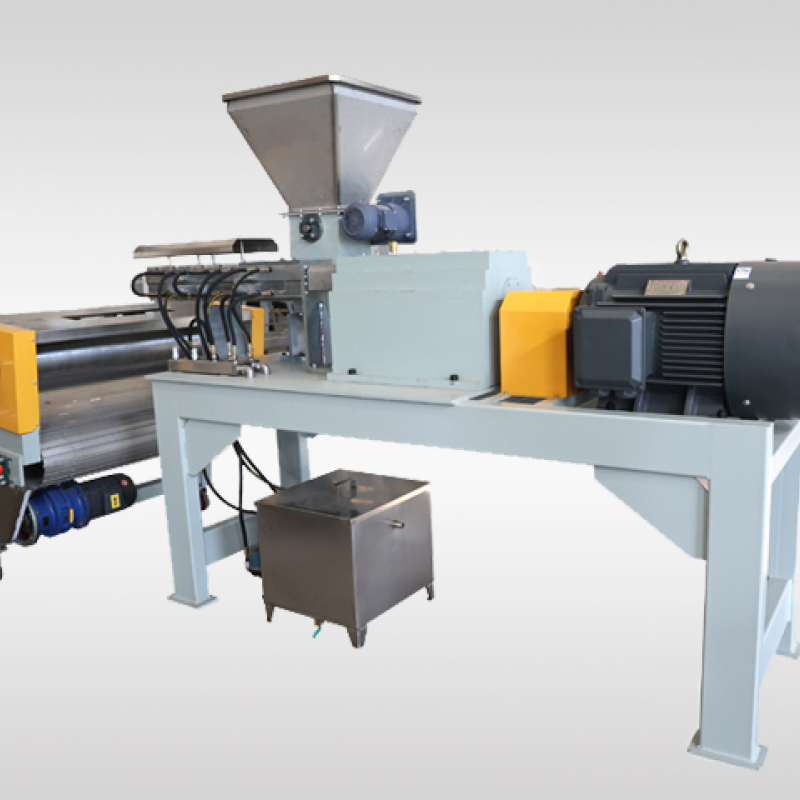

Extruder machine is a widely used equipment in industrial production, especially in the processing of plastics, rubber and other materials play an indispensable role. This extruder adopts the design of single-screw upper feeding, which not only improves the feeding efficiency, but also ensures the uniformity of feeding.

Contact Now

Extruder machine for powder coating is a device used to produce or process powder coating. It is commonly used to manufacture powder coatings, but can also be used to modify or reprocess existing powder coatings. The following is the general working principle and main characteristics of the extruder:First.

Contact Now

SLJ twin screw extruder has the following advantages:1. High production efficiency: SLJ twin screw extruder adopts twin screw structure, with greater extrusion capacity and higher extrusion speed. Compared with a single screw extruder, it can produce more plastic products in the same time, improving production efficiency.2. Good mixing performance: The twin screw extruder can better mix plastic raw materials through two mutually integrated rotating screws. This ensures the uniform distribution and full integration of raw materials and improves the quality of finished products.3.

Contact Now

Extruder machines play a vital role in the production of thermoset powder coatings, especially in the thermal micro homogeneous mixing and reaction processes. The following is a detailed explanation of the application of extruders in this field:First of all, thermosetting powder coatings are a special type of coating which is capable of curing into a hard coating under heated conditions. This type of coating needs to achieve microscopic homogeneous mixing during the production process to ensure that the coating's various performance indicators meet the requirements.

Contact Now

Product Details Of Powder Coating Extruder JCJ30:Before the extruder starts offevolved to work every time, flip the motor with the crank manage to see if the rotation is effortless and labor-saving. Otherwise, it need to be saved at the method temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder begins to work, the screw runs at a low velocity and feeds a little.

Contact Now

Single screw reciprocating extruder has the following advantages:1. Efficient production: single screw reciprocating extruder adopts reciprocating motion design, through the reciprocating extrusion action, can achieve high-speed and efficient production of plastic products. Compared to traditional single-screw extruders, reciprocating extruders can produce more product in the same amount of time.2. Energy saving: The design of the single-screw reciprocating extruder makes the use of energy more efficient.

Contact Now

Technical characteristics of this powder coating extruder:The powder coating extruder, as a high-precision mechanical equipment, occupies a pivotal position in the material processing industry. Its technical characteristics are not only reflected in efficient processing capabilities, but also demonstrate its excellent performance in details.Before each start, the machine performs a pre-rotation check on the motor through the turning crank. This step may seem simple, but it greatly improves the stability and safety of the equipment.

Contact Now

Product Details Of Powder Coating Extruder JCJ75: Before the extruder starts offevolved to work every time, flip the motor with the crank cope with to see if the rotation is handy and labor-saving. Otherwise, it ought to be saved at the procedure temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder starts offevolved to work, the screw runs at a low velocity and feeds a little.

Contact Now

Product Details Of Powder Coating Extruder JCJ63: Earlier than the extruder begins to paintings each time, turn the motor with the crank handle to see if the rotation is straightforward and exertions-saving. In any other case, it ought to be stored on the manner temperature for 3 to 5 minutes, till the rotation is exertions-saving, and then it's far allowed to start operation.Each time the extruder starts offevolved to paintings, the screw runs at a low speed and feeds a touch.

Contact Now

A laboratory extruder is a device specially designed for the extrusion process in laboratory research and small-scale production. It has several advantages:1. Flexibility and adjustability: Laboratory extruders can usually provide a wide range of operating parameters and adjustable extrusion process parameters, such as extrusion pressure, extrusion speed, temperature control, etc. This allows researchers to precisely control and adjust the extrusion process as needed to obtain the desired material properties and product properties.2.

Contact Now

Powder mixer for mixing vrious materials have the following advantages:1. Uniform mixing: The mixer can uniformly mix a variety of different materials, ensuring that each particle or molecule can be fully contacted and mixed. This improves the quality of the product and eliminates unevenness and inconsistency.2. Improve efficiency: The machine can complete the mixing process in a relatively short time, greatly improving production efficiency. A fast and efficient mixing process reduces production cycle times and increases production throughput.3.

Contact Now

Automatic slicing compound feeding machine has the following advantages:1. High efficiency: The machine can automatically slice, compound and feed operations, greatly improving the production efficiency.2. Precision: The machine can precisely control the cutting and compounding of materials, thus ensuring the quality and stability of the product.3. Automation: The machine can automatically complete multiple processes, reducing manual operation and reducing production costs.4.

Contact Now

Our powder coating machine, relying on its independent research and development innovation capabilities, has demonstrated its significant advantages in the field of spray coating. During the production and processing of this equipment, we always adhere to high standards of quality requirements to ensure excellence in every process, thereby creating high-quality products.The biggest highlight of this powder coating machine is its personalized production capabilities. We are committed to tailoring exclusive spraying equipment to customers based on their actual uses and site requirements.

Contact Now

The grinding machine has the following main advantages:1. High efficiency: The powder mill crushes raw materials or materials through mechanical force, and can quickly convert large pieces of materials into the required fine powder. This improves production efficiency and processing speed, saving time and labor costs.2. Adjustable particle size: It usually have an adjustable outlet size or device, which can adjust the particle size of the particles produced as needed.

Contact Now

The working principle of the 500KG powder grinding machine is carefully designed and manufactured, and its core mechanism mainly relies on the friction and impact of the material between the high-speed rotating mill disc and the fixed grinding ring. When the motor starts and the driving spindle begins to rotate, the material on the mill disk is quickly thrown to the grinding ring due to the role of centrifugal force.

Contact Now

Automated processing has several advantages:1. High precision: During the machining process, through precise machine tool and cutting tool control, high-precision machining can be achieved to meet strict requirements for size, shape and surface quality. The stability of the machine tool and the high-precision motion system ensure the accuracy and repeatability of the workpiece.2. Diversity: Automated processing is suitable for a variety of materials, including metals, plastics, ceramics, and more.

Contact Now

Product information:It is appropriate for the final step in the creation of thermosetting electrostatic powder coating, which is grinding. The powder machine uses high-speed impact crushing, air classification to control the outlet material particles, cyclone separation to separate the fine particles, sieving to separate the coarse slag from the main particle size powder, and an ultra-fine powder collector to catch any fine powder that escapes the system. Excellent ventilation.

Contact Now

Product Details:When the powder machine is working, the materials entering the grinding area of the grinding disc are crushed by the impact column, and under the action of the suction of the induced draft fan, they go up and down along the two sides of the return circle and enter the separation area to be sprayed out from the material outlet through the fan separator. Due to the high-speed rotation of the fan blade separator, the centrifugal force generated hinders the passage of materials.

Contact Now

Multi layer slicing automatic composite feeding machine has the following advantages:1. High efficiency: The equipment can realize automatic slicing and compounding process, which greatly improves production efficiency and work efficiency. Compared to manual operation, automated equipment can complete tasks faster and can continue to operate without operator fatigue or rest.2. Accuracy: The multi layer slicing automatic composite feeding machine adopts advanced control and positioning technology, which can achieve high-precision cutting and composite.

Contact Now

Product Details:Powder machine MFJ20 is appropriate for the remaining manner in the manufacturing technique of thermosetting electrostatic powder coating - grinding production. The device adopts high-speed have an impact on crushing, air classification controls the outlet cloth particles, cyclone separation separates the fantastic particles, the foremost particle dimension powder is sieved to separate the coarse slag, and the ultra-fine powder collector collects the great powder and ensures that the first-class powder in the device does now not leak out. Good ventilation.

Contact Now

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.3.

Contact Now

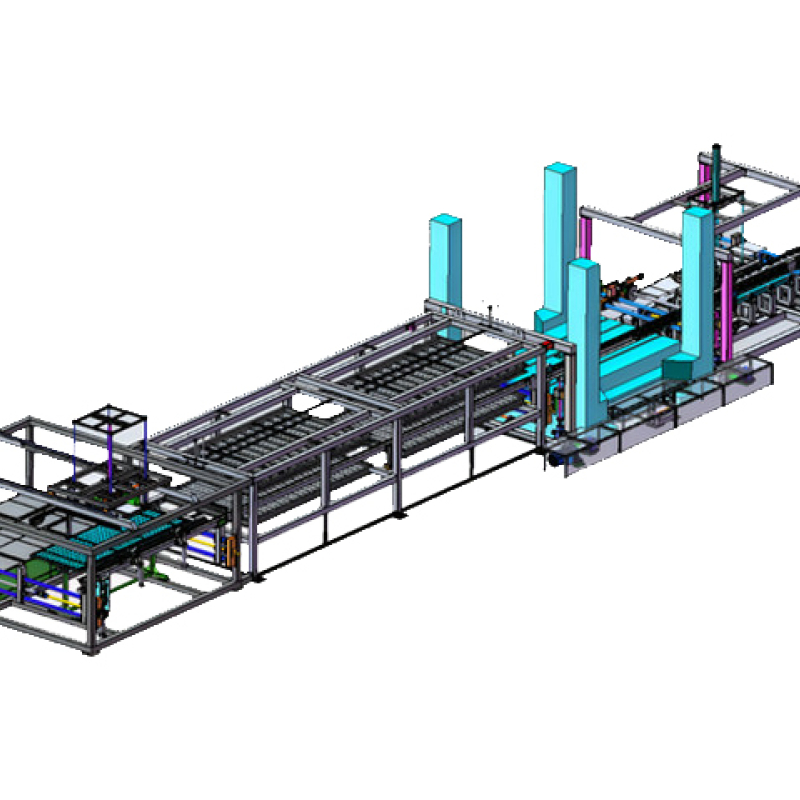

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

Product DetailsCooling belt YPJ800 is driven through a frequency conversion motor, and the sprocket is pushed via a reducer. the discount gadget drives the nodal stainless steel conveyor belt, the pill roller, and the crushing curler to move synchronously.The material extruded by the extruder falls vertically among the two rollers, and as the curler rotates, the new material is brought into the gap among the rollers for extrusion.

Contact Now

The sheet forming machine has the following advantages:1. With the function of automatic rotation and tablet pressing, it enters the hopper through the closed barrel and the closed conveying system, and takes effective measures to prevent dust flying and particle stratification during the tablet pressing process. The pressed tablet enters the packaging process through the screen, chip detection, metal detection, etc. The whole process is quite closed.2. The sheet forming machine has a start, end and speed adjustment function.

Contact Now