HLJ type powder blending equipment is highly regarded for its excellent mixing performance and wide range of applications. As the first key equipment in the electrostatic powder coating production line, it undertakes the important task of mixing various materials evenly. Whether it is HLJ300, HLJ500 or HLJ800, each model has its unique features and advantages to meet the different scale and production requirements of the coating line.Model HLJ300 is suitable for small to medium sized production lines.

Contact Now

A container mixer is a device often used to achieve material mixing and uniform mixing. The following is a detailed description of the container mixer:1. How it works: Container mixers usually consist of a large container and mixing equipment. The material is placed in the container, and then the mixing equipment is activated to mix and stir the material to ensure that the ingredients are fully mixed.2. Applicable materials: The container mixer is suitable for mixing materials of powder, particles, pigments, granular materials, suspended materials and other forms and properties.

Contact Now

The charm of the powder mixer, as a right-hand man in the industrial field, lies in its omnipotent mixing ability. Whether it is hard solids or fine powders, it can skillfully blend them together and show amazing mixing effects. Its powerful mixing ability makes all kinds of materials to be evenly mixed, and achieves the ideal mixing state, which ensures the high quality and stability of the products.The thoroughness of mixing is undoubtedly a highlight of the powder mixer.

Contact Now

Automatic mixer has the following characteristics and advantages:1. Efficient mixing: The automatic mixer can efficiently mix different materials to achieve uniform distribution and consistency, and improve production efficiency and product quality.2. Reduce manual intervention: Compared with manual mixing, automatic mixing machine can reduce manual operation and intervention, improve work efficiency, and reduce the risk of human operation error.3.

Contact Now

In the electrostatic powder coating production line,powder mixer blender is undoubtedly the equipment that plays a vital role. With its unique advantages, it brings a lot of convenience and benefits to the whole production process.First of all, the powder mixer blender, with its efficient mixing performance, ensures that a variety of materials can be evenly mixed in a short period of time. This makes it possible to precisely control the proportion of the coating components, thus substantially improving the quality of the coating.

Contact Now

The design of the dry powder mixer's barrel is ingenious, with every detail carefully polished to ensure that the structure is tightly and securely connected without any unnecessary gaps. This design not only greatly enhances the stability and safety of the cylinder during transportation, but also maintains its excellent performance in long-term use.It is worth mentioning that the loading and unloading design of the machine is very innovative.

Contact Now

Powder mixer for mixing vrious materials have the following advantages:1. Uniform mixing: The mixer can uniformly mix a variety of different materials, ensuring that each particle or molecule can be fully contacted and mixed. This improves the quality of the product and eliminates unevenness and inconsistency.2. Improve efficiency: The machine can complete the mixing process in a relatively short time, greatly improving production efficiency. A fast and efficient mixing process reduces production cycle times and increases production throughput.3.

Contact Now

Product details of powder processing high speed mixer blender HLJ500Partial composition:(1) Mixing tank.(2) Rack.(3) Stirring motor.(4) Reducer.(5) Crushing motor.(6) Discharging port.Using a reducer, the stirring paddle is propelled at a speed of 85 rpm. The motor's speed of 2900 rpm allows the crushing to be pushed immediately. With the help of the time relay, the mixing time can be set.Product Parameters:modelHLJ500Material cylinder diameter (mm)1250Capacity (kg)500Host power (kw)22Crushing motor power (kw)7.5Output (kg/h)1600

Contact Now

Extruder machines play a vital role in the production of thermoset powder coatings, especially in the thermal micro homogeneous mixing and reaction processes. The following is a detailed explanation of the application of extruders in this field:First of all, thermosetting powder coatings are a special type of coating which is capable of curing into a hard coating under heated conditions. This type of coating needs to achieve microscopic homogeneous mixing during the production process to ensure that the coating's various performance indicators meet the requirements.

Contact Now

Product info of powder processing high speed mixer blender HLJ800Somewhat composed:(1) A tank for mixing.(2) rack.(3) a motor that stirs.(4) Reducer.(5) A motor for crushing.(6) A port for discharge.At a speed of 85 rpm, the stirring paddle is forced via a reduction. The motor's 2900 rpm speed helps push the crushing forward without delay. With the help of the time relay, the mixing time can be set.Product Parameters:modelHLJ800Material cylinder diameter (mm)1250Capacity (kg)500Host power (kw)22Crushing motor power (kw)7.5Output (kg/h)1600

Contact Now

Partial composition of powder processing high speed mixer blender HLJ300:(1) Mixing tank.(2) Rack. (3) A motor that stirs. (4) Reducer. (5) Motor for crushing. (6) Port for discharging.A reducer spinning at 85 revolutions per minute powers the stirring paddle. With a speed of 2900 rpm, the motor directly drives the crusher. With the help of the time relay, the mixing time can be set.Product Parameters:modelHLJ300Material cylinder diameter (mm)1250Capacity (kg)500Host power (kw)22Crushing motor power (kw)7.5Output (kg/h)1600

Contact Now

One of the significant advantages of this spiral cooling conveyor with its impressive performance parameters is the use of advanced frequency-controlled motor drive technology. This technology not only ensures the stability and reliability of the machine, but also gives the machine excellent working efficiency and adjustment flexibility.

Contact Now

Automated processing has several advantages:1. High precision: During the machining process, through precise machine tool and cutting tool control, high-precision machining can be achieved to meet strict requirements for size, shape and surface quality. The stability of the machine tool and the high-precision motion system ensure the accuracy and repeatability of the workpiece.2. Diversity: Automated processing is suitable for a variety of materials, including metals, plastics, ceramics, and more.

Contact Now

Product advantages of machining fixturing:1. Assembly Nest and Tools.2. CMM Holding Fixtures.3. Photometric Holding Fixtures.4. Custom Vacuum Pads and Machine Seals.5. ESD Dissipative 3D Printed Nest and Tools.6. Validation and Testing Fixtures.7. In-Process Quality Check Tools.8. Poka-Yoke.9. T-Slot Equipment Design and Assembly (8020).10. Machine Guards.11. Organization and 5S equipment.

Contact Now

Hydraulic station supporting silent room is a specially designed soundproof room used to deal with noise problems on industrial assembly lines. It has the following advantages:1. Reduce noise interference: hydraulic station equipment usually produces a high noise level, and the silent room uses soundproof materials and structural design, which can effectively absorb, isolate and reduce the spread of noise. This can reduce noise interference to the surrounding environment and staff, providing a relatively quiet working environment.2.

Contact Now

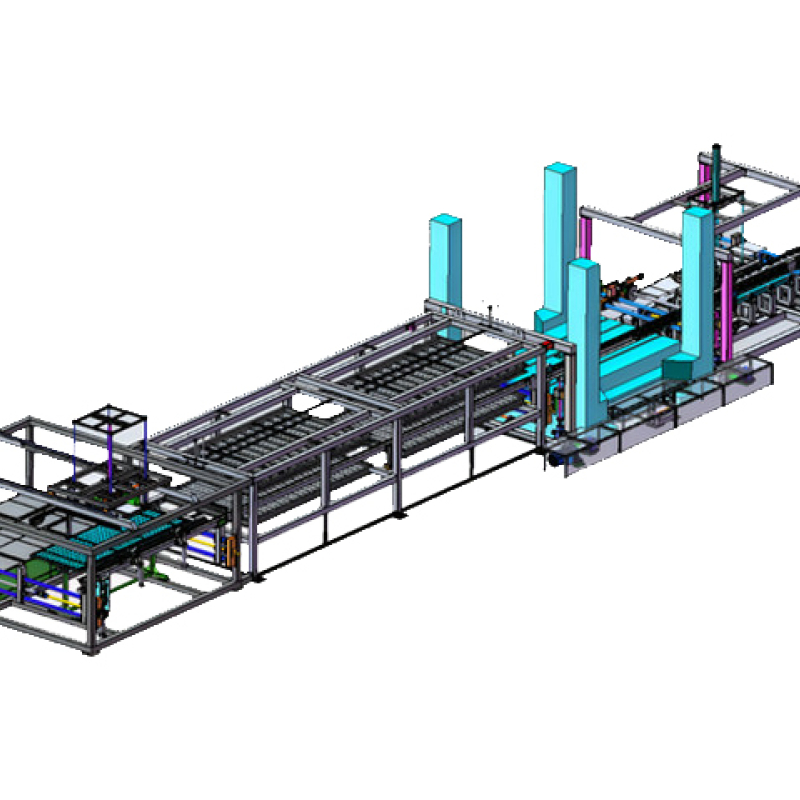

The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Multi layer slicing automatic composite feeding machine has the following advantages:1. High efficiency: The equipment can realize automatic slicing and compounding process, which greatly improves production efficiency and work efficiency. Compared to manual operation, automated equipment can complete tasks faster and can continue to operate without operator fatigue or rest.2. Accuracy: The multi layer slicing automatic composite feeding machine adopts advanced control and positioning technology, which can achieve high-precision cutting and composite.

Contact Now

Characteristics of the bulk powder handling equipment:1. Integrated grinding and classifying machine.2. Compact, space-saving design.3. Stable and narrow particle size distribution and simple adjustment.4. Cutting accuracy is easy to adjust.5. High availability and automation levels.6. Automatic pneumatic feeding system saves time and effort.7. low noise emission.8. Low specific energy consumption.9. Wear protection.10. Environmentally friendly design to minimize ultrafine emissions.11. Easy to clean and maintain.

Contact Now

Automatic slicing compound feeding machine has the following advantages:1. High efficiency: The machine can automatically slice, compound and feed operations, greatly improving the production efficiency.2. Precision: The machine can precisely control the cutting and compounding of materials, thus ensuring the quality and stability of the product.3. Automation: The machine can automatically complete multiple processes, reducing manual operation and reducing production costs.4.

Contact Now

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.3.

Contact Now

The main parameters of car roof multi-layer automatic slicing compound feeding machine:1. A-B fiberglass pulling and rubber roller feeding adopt servo motor plus synchronous belt mechanism; station movement and stacking table transmission mechanism adopt motor plus frequency converter plus synchronous belt mechanism.2. The lifting and traversing trolley of the PU board is controlled by a frequency conversion motor, and the rotation is controlled by a servo motor.3. Product size range: the maximum product size is 2500*1500mm, and the minimum product size is 1200*860mm.4.

Contact Now

Equipment sheet metal parts have the following advantages:1. Lightweight: Compared with traditional casting, forging and other processes, sheet metal processing products are usually made of thin plate metal materials and have lower weight. They can achieve lightweight design of the product while ensuring structural strength. They are suitable for Application scenarios that require light weight and resource saving.2. High strength: Through reasonable design and processing technology, sheet metal processing products can effectively improve their strength and rigidity.

Contact Now

Product advantages:1. Can improve the production yield rate of enterprises.For manufacturing companies, whether they produce equipment products themselves or use equipment to produce specific products, if machined parts are integrated, the product yield rate will be much higher than that of general equipment. This is mainly due to the good reputation of machined parts. With higher precision, the equipment composed of these parts will naturally have higher precision, and the quality of the products produced will definitely be more guaranteed.2.

Contact Now

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now