In modern industrial manufacturing, powder coating equipment has become an indispensable and important tool, especially in the pursuit of efficient and environmentally friendly production environment. Our self-developed powder coating equipment has won wide recognition in the market due to its excellent production and processing quality, strict quality control and unique environmental protection features.During the research and development process, we pay attention to every detail, from the selection of materials to the production process, and strive for excellence.

Contact Now

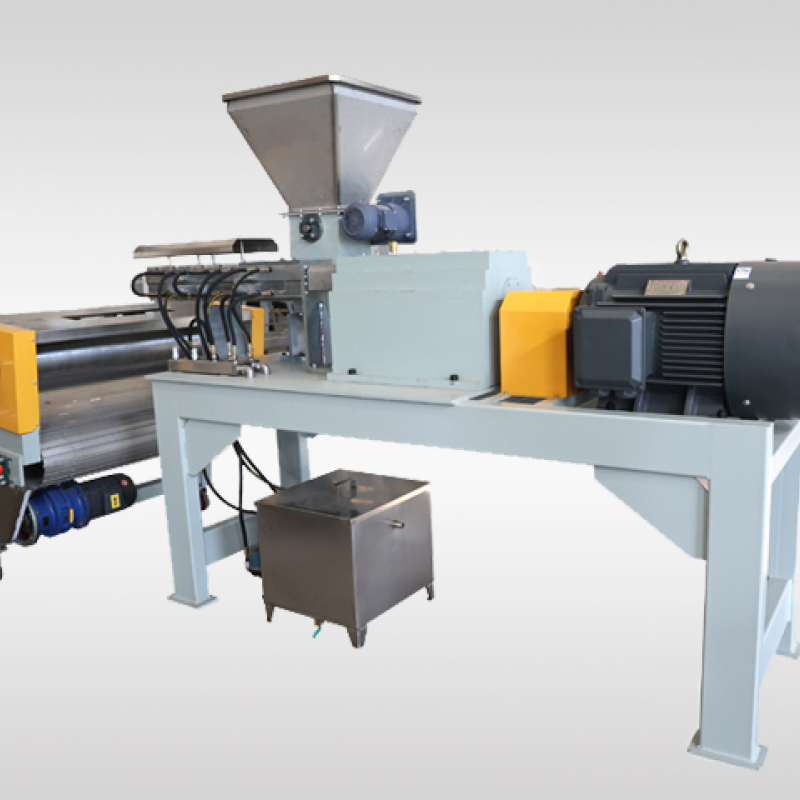

Technical characteristics of this powder coating extruder:The powder coating extruder, as a high-precision mechanical equipment, occupies a pivotal position in the material processing industry. Its technical characteristics are not only reflected in efficient processing capabilities, but also demonstrate its excellent performance in details.Before each start, the machine performs a pre-rotation check on the motor through the turning crank. This step may seem simple, but it greatly improves the stability and safety of the equipment.

Contact Now

Our powder coating machine, relying on its independent research and development innovation capabilities, has demonstrated its significant advantages in the field of spray coating. During the production and processing of this equipment, we always adhere to high standards of quality requirements to ensure excellence in every process, thereby creating high-quality products.The biggest highlight of this powder coating machine is its personalized production capabilities. We are committed to tailoring exclusive spraying equipment to customers based on their actual uses and site requirements.

Contact Now

The technical advantages of powder spraying equipment are significant, especially in terms of environmental performance. Compared to traditional coating methods, powder spraying technology undoubtedly demonstrates a higher degree of environmental friendliness. Traditional spraying methods are often accompanied by the emission of harmful gases and wastewater, posing a potential threat to the environment and human health.

Contact Now

HLJ type powder blending equipment is highly regarded for its excellent mixing performance and wide range of applications. As the first key equipment in the electrostatic powder coating production line, it undertakes the important task of mixing various materials evenly. Whether it is HLJ300, HLJ500 or HLJ800, each model has its unique features and advantages to meet the different scale and production requirements of the coating line.Model HLJ300 is suitable for small to medium sized production lines.

Contact Now

In the electrostatic powder coating production line,powder mixer blender is undoubtedly the equipment that plays a vital role. With its unique advantages, it brings a lot of convenience and benefits to the whole production process.First of all, the powder mixer blender, with its efficient mixing performance, ensures that a variety of materials can be evenly mixed in a short period of time. This makes it possible to precisely control the proportion of the coating components, thus substantially improving the quality of the coating.

Contact Now

Extruder machine for powder coating is a device used to produce or process powder coating. It is commonly used to manufacture powder coatings, but can also be used to modify or reprocess existing powder coatings. The following is the general working principle and main characteristics of the extruder:First.

Contact Now

Product Details Of Powder Coating Extruder JCJ30:Before the extruder starts offevolved to work every time, flip the motor with the crank manage to see if the rotation is effortless and labor-saving. Otherwise, it need to be saved at the method temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder begins to work, the screw runs at a low velocity and feeds a little.

Contact Now

Product Details Of Powder Coating Extruder JCJ63: Earlier than the extruder begins to paintings each time, turn the motor with the crank handle to see if the rotation is straightforward and exertions-saving. In any other case, it ought to be stored on the manner temperature for 3 to 5 minutes, till the rotation is exertions-saving, and then it's far allowed to start operation.Each time the extruder starts offevolved to paintings, the screw runs at a low speed and feeds a touch.

Contact Now

Product Details Of Powder Coating Extruder JCJ75: Before the extruder starts offevolved to work every time, flip the motor with the crank cope with to see if the rotation is handy and labor-saving. Otherwise, it ought to be saved at the procedure temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder starts offevolved to work, the screw runs at a low velocity and feeds a little.

Contact Now

Performance characteristics of flour millFlour mill occupies a pivotal position in the production of thermosetting electrostatic powder coatings. As the grand finale of the entire production process, it is responsible for the fine grinding of raw materials into high quality coatings. By virtue of its precise grinding ability, the mill can ensure that the fineness and uniformity of the coating product reaches the highest standard, thus meeting the market demand for high-quality coatings.The flour mill's efficient working principle is the key to its excellent performance.

Contact Now

The barrel design of the extrusion equipment is ingenious, it adopts a fully hinged folio tile liner structure, this innovative design not only enhances the overall structural strength of the equipment, making the machine more robust and durable, but also greatly improves the convenience of clearing, installation and maintenance.

Contact Now

Characteristic of powder dispensing equipment:1. The main grinding adopts double-layer thickened noise-reducing grinding body, with low noise.2. High output.3. Concentrated, stable and adjustable particle size distribution.4. Low loss rate, ≤ 2%.5. The temperature rise of the mill is small, and the powder temperature is low.6. Both the front end and the rear end of the mill can be equipped with auxiliary feeding devices.7. Touch screen and PLC control, friendly man-machine interface, easy to operate.8. Grinding body temperature monitoring.9. Perfect security protection system.10.

Contact Now

Extruder machines play a vital role in the production of thermoset powder coatings, especially in the thermal micro homogeneous mixing and reaction processes. The following is a detailed explanation of the application of extruders in this field:First of all, thermosetting powder coatings are a special type of coating which is capable of curing into a hard coating under heated conditions. This type of coating needs to achieve microscopic homogeneous mixing during the production process to ensure that the coating's various performance indicators meet the requirements.

Contact Now

Characteristics of the bulk powder handling equipment:1. Integrated grinding and classifying machine.2. Compact, space-saving design.3. Stable and narrow particle size distribution and simple adjustment.4. Cutting accuracy is easy to adjust.5. High availability and automation levels.6. Automatic pneumatic feeding system saves time and effort.7. low noise emission.8. Low specific energy consumption.9. Wear protection.10. Environmentally friendly design to minimize ultrafine emissions.11. Easy to clean and maintain.

Contact Now

The charm of the powder mixer, as a right-hand man in the industrial field, lies in its omnipotent mixing ability. Whether it is hard solids or fine powders, it can skillfully blend them together and show amazing mixing effects. Its powerful mixing ability makes all kinds of materials to be evenly mixed, and achieves the ideal mixing state, which ensures the high quality and stability of the products.The thoroughness of mixing is undoubtedly a highlight of the powder mixer.

Contact Now

Main advantages of drying equipment in factories:1. Consistent product quality: The tablet press can evenly compress powder or granular materials into consistent tablets, granules or other shaped solid products. This ensures consistent quality for each product, eliminating variations that may occur during manual production.2. High production efficiency: The tablet press can perform continuous production at a high speed. They usually have automated control systems that enable efficient raw material feeding, pressing and product discharge, thereby improving production efficiency.3.

Contact Now

Product information:It is appropriate for the final step in the creation of thermosetting electrostatic powder coating, which is grinding. The powder machine uses high-speed impact crushing, air classification to control the outlet material particles, cyclone separation to separate the fine particles, sieving to separate the coarse slag from the main particle size powder, and an ultra-fine powder collector to catch any fine powder that escapes the system. Excellent ventilation.

Contact Now

Product Details:Powder machine MFJ20 is appropriate for the remaining manner in the manufacturing technique of thermosetting electrostatic powder coating - grinding production. The device adopts high-speed have an impact on crushing, air classification controls the outlet cloth particles, cyclone separation separates the fantastic particles, the foremost particle dimension powder is sieved to separate the coarse slag, and the ultra-fine powder collector collects the great powder and ensures that the first-class powder in the device does now not leak out. Good ventilation.

Contact Now

The design of the dry powder mixer's barrel is ingenious, with every detail carefully polished to ensure that the structure is tightly and securely connected without any unnecessary gaps. This design not only greatly enhances the stability and safety of the cylinder during transportation, but also maintains its excellent performance in long-term use.It is worth mentioning that the loading and unloading design of the machine is very innovative.

Contact Now

A container mixer is a device often used to achieve material mixing and uniform mixing. The following is a detailed description of the container mixer:1. How it works: Container mixers usually consist of a large container and mixing equipment. The material is placed in the container, and then the mixing equipment is activated to mix and stir the material to ensure that the ingredients are fully mixed.2. Applicable materials: The container mixer is suitable for mixing materials of powder, particles, pigments, granular materials, suspended materials and other forms and properties.

Contact Now

Advantages of powder handling systems:1. Improve production efficiency: Powder handling systems can automatically complete the processing, transportation and storage of materials to improve production efficiency.2. Ensure product quality: Powder handling systems can be customized according to different material characteristics and processing requirements to ensure the stability and consistency of product quality.3. Reduce manual operations: It can automatically complete the processing and transportation process of materials, reducing manual operations, labor intensity and human errors.4.

Contact Now

Performance characteristics of powder handling:1. Compared with airflow mill, powder handling has a wider scope of application.2. Compared with other similar mills, the grinding force of the grinding roller on the material is increased by 800-1200Kg under the action of high-pressure spring.3. Energy saving (under the same output and fineness, the system energy consumption is only one-third of that of airflow mill).4. Small investment, high returns.5. The feeding particle size is large, and the average particle size of the discharged material can reach ultra-fine powder of <6.5um.6.

Contact Now

The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now