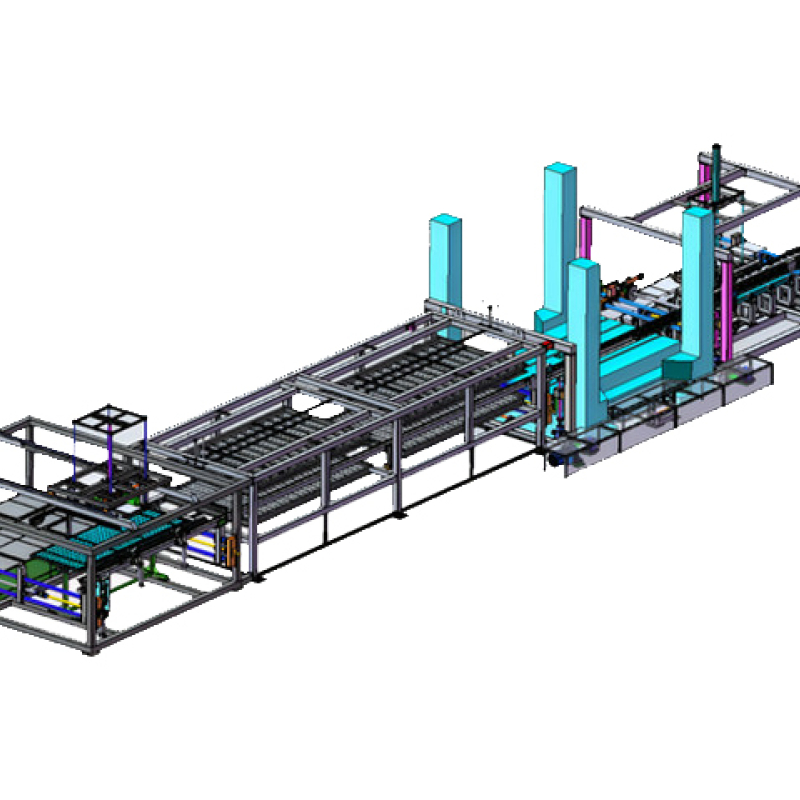

Car roof dry automatic molding line mainly includes: substrate loader, conveying system (including girder lifting and width adjustment system), two-stage heating and drying furnace, auxiliary material table, mold centering device, mold changing car, printer table, work Steps and safety protection devices, etc.skills requirement:1. The largest substrate and fabric size: 2950×1800mm.2. The production cycle meets the requirement of 45-60 seconds/piece.3. The horizontal height of substrate transmission: 1320mm.4.

Contact Now

The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

The main parameters of car roof multi-layer automatic slicing compound feeding machine:1. A-B fiberglass pulling and rubber roller feeding adopt servo motor plus synchronous belt mechanism; station movement and stacking table transmission mechanism adopt motor plus frequency converter plus synchronous belt mechanism.2. The lifting and traversing trolley of the PU board is controlled by a frequency conversion motor, and the rotation is controlled by a servo motor.3. Product size range: the maximum product size is 2500*1500mm, and the minimum product size is 1200*860mm.4.

Contact Now

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.3.

Contact Now

Auto trunk cover plate automatic edge wrapping equipment has the following advantages:1. Improve production efficiency: Auto trunk cover plate automatic edge wrapping equipment can greatly improve production efficiency. Compared to manual assembly, automated systems can complete each step of roof assembly quickly and accurately.

Contact Now

Auto ceiling accessories automatic assembly equipment:1. Improve production efficiency: Auto ceiling accessories automatic assembly equipment can quickly and accurately complete the assembly of car roofs, thereby improving production efficiency.2. Reduce labor costs: Compared with manual assembly, auto ceiling accessories automatic assembly equipment can reduce manual participation and reduce labor costs.3. Improve product quality: Automatic assembly equipment can ensure the consistency and accuracy of assembly, thereby improving product quality.4.

Contact Now

Automotive ceiling automatic PU board equipment has many advantages:1. Automatic operation: The equipment adopts automatic technology, which can realize the automatic positioning, pasting and pressing of PU sheet without too much manual operation. This greatly increases productivity and reduces the risk of human error.2. Accurate paste position: The equipment is equipped with an accurate positioning system, which can accurately locate the position of the car ceiling to ensure the accuracy of PU sheet paste.

Contact Now

Metal parts have the following advantages:1. Lightweight: Metal parts are typically made of skinny sheet steel and are lighter in weight than different substances (such as castings). This makes sheet steel fabricated merchandise very nice in purposes the place module or usual weight discount is required, such as in the car and aerospace sectors.2. High precision: The sheet steel processing manner can acquire exceedingly particular dimensional control, thereby making sure that the processed merchandise have excessive precision and matching.

Contact Now

In modern industrial manufacturing, powder coating equipment has become an indispensable and important tool, especially in the pursuit of efficient and environmentally friendly production environment. Our self-developed powder coating equipment has won wide recognition in the market due to its excellent production and processing quality, strict quality control and unique environmental protection features.During the research and development process, we pay attention to every detail, from the selection of materials to the production process, and strive for excellence.

Contact Now

The technical advantages of powder spraying equipment are significant, especially in terms of environmental performance. Compared to traditional coating methods, powder spraying technology undoubtedly demonstrates a higher degree of environmental friendliness. Traditional spraying methods are often accompanied by the emission of harmful gases and wastewater, posing a potential threat to the environment and human health.

Contact Now

Multi layer slicing automatic composite feeding machine has the following advantages:1. High efficiency: The equipment can realize automatic slicing and compounding process, which greatly improves production efficiency and work efficiency. Compared to manual operation, automated equipment can complete tasks faster and can continue to operate without operator fatigue or rest.2. Accuracy: The multi layer slicing automatic composite feeding machine adopts advanced control and positioning technology, which can achieve high-precision cutting and composite.

Contact Now

The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now

HLJ type powder blending equipment is highly regarded for its excellent mixing performance and wide range of applications. As the first key equipment in the electrostatic powder coating production line, it undertakes the important task of mixing various materials evenly. Whether it is HLJ300, HLJ500 or HLJ800, each model has its unique features and advantages to meet the different scale and production requirements of the coating line.Model HLJ300 is suitable for small to medium sized production lines.

Contact Now

Toyota Eifang RAV4 line speed transmission line has the following advantages:1. Improve production efficiency: The line speed transmission line uses an automated way to transmit the vehicle or vehicle parts from one workstation to another in an uninterrupted state, reducing the pause time in the production process and improving production efficiency.2. Quality control: Through the use of line speed transmission lines, Toyota can achieve strict control over the production process to ensure that each vehicle is assembled and inspected in accordance with standard procedures.

Contact Now

Characteristics of the bulk powder handling equipment:1. Integrated grinding and classifying machine.2. Compact, space-saving design.3. Stable and narrow particle size distribution and simple adjustment.4. Cutting accuracy is easy to adjust.5. High availability and automation levels.6. Automatic pneumatic feeding system saves time and effort.7. low noise emission.8. Low specific energy consumption.9. Wear protection.10. Environmentally friendly design to minimize ultrafine emissions.11. Easy to clean and maintain.

Contact Now

Characteristic of powder dispensing equipment:1. The main grinding adopts double-layer thickened noise-reducing grinding body, with low noise.2. High output.3. Concentrated, stable and adjustable particle size distribution.4. Low loss rate, ≤ 2%.5. The temperature rise of the mill is small, and the powder temperature is low.6. Both the front end and the rear end of the mill can be equipped with auxiliary feeding devices.7. Touch screen and PLC control, friendly man-machine interface, easy to operate.8. Grinding body temperature monitoring.9. Perfect security protection system.10.

Contact Now

The electrical cabinet chassis has the following product advantages:1. Protection performance: The electrical cabinet chassis can provide good physical protection and protect the internal electrical equipment from external dust, moisture, vibration and other damaging factors. They are usually dustproof, waterproof, anti-corrosion and other functions to protect the normal operation of equipment and extend its life.2. Safety: The design of the electrical cabinet chassis takes into account electrical safety and human safety.

Contact Now

Powder mixer for mixing vrious materials have the following advantages:1. Uniform mixing: The mixer can uniformly mix a variety of different materials, ensuring that each particle or molecule can be fully contacted and mixed. This improves the quality of the product and eliminates unevenness and inconsistency.2. Improve efficiency: The machine can complete the mixing process in a relatively short time, greatly improving production efficiency. A fast and efficient mixing process reduces production cycle times and increases production throughput.3.

Contact Now

The advantages of jig and fixtures encompass however are no longer restricted to the following:1. Increase in production.2. The steady fine of manufactured merchandise due to low variability in dimension.3. Cost reduction.4. Inter-changeability and excessive accuracy of parts.5. Inspection and satisfactory manipulate fees are extensively reduced.6. The limit in an accident with multiplied protection standards.7. Due to extraordinarily easy maneuverability, semi-skilled employees can function these tools, decreasing the workforce's cost.8.

Contact Now

Advantages of CNC machining:1. High repeatability and precision.2. Volume of manufacturing is very high.3. Complex contours/surfaces want to be machined.etc..4. Flexibility in job change, computerized device settings, much less scrap.5. More safe, greater productivity, higher quality.6. Less paper work, quicker prototype production, reduction in lead instances.

Contact Now

Advantages of CNC machining working:CNC machining working is a manufacturing process widely used for prototypes and production parts. This is thanks to several factors, including cost, time and the specific mechanical advantages of machined parts.1. Accuracy.Because CNC machines follow computer instructions, they are very precise. Most CNC machines have an accuracy of around 0.02 mm, which means complex parts can be manufactured to very tight tolerances. Eliminating errors is a top priority for manufacturers, and CNC machines greatly reduce the likelihood of errors.2.

Contact Now

Product advantages:1. Strong bearing capacity: After design and calculation, the connecting bearing can bear the load capacity of the building structure, including gravity load, horizontal load and shear force. They can effectively transfer and disperse loads, ensuring the stability and safety of the structure.2. Shock absorption and energy absorption capabilities: The connection supports can have shock absorption and energy absorption functions to reduce the impact of external factors such as earthquakes and wind loads on the structure.

Contact Now

The mobile silent room has the following advantages:1. Flexibility: The mobile silent room can be moved to different locations at any time to adapt to different needs and environments. Whether it needs to be used in different worksites or arranged in different sites, mobile silent rooms offer the flexibility and convenience to be arranged and relocated at any time.2. Customizability: The mobile silent room can usually be customized according to the needs of users to meet different functional needs and design preferences.

Contact Now