Vacuum adsorption gluing mold has the following advantages:1. Uniform gluing pressure: The vacuum adsorption mold can achieve uniform gluing pressure on thin plates or thin materials through uniform air pressure distribution. This helps reduce deformation and warping during the gluing process, allowing for more accurate size and shape of the glued parts.2. High-quality adsorption effect: The vacuum system provides strong adsorption, which firmly adsorbs thin plates or thin materials to the mold surface.

Contact Now

The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now

Powder mixer for mixing vrious materials have the following advantages:1. Uniform mixing: The mixer can uniformly mix a variety of different materials, ensuring that each particle or molecule can be fully contacted and mixed. This improves the quality of the product and eliminates unevenness and inconsistency.2. Improve efficiency: The machine can complete the mixing process in a relatively short time, greatly improving production efficiency. A fast and efficient mixing process reduces production cycle times and increases production throughput.3.

Contact Now

1. Fast processing speed.The most significant advantage of sheet metal processing technology is that the cutting speed is fast and is not limited by the number of processes. But it is more suitable in the production process, because it does not waste time changing tools and effectively increases the processing speed; to a certain extent, its processing speed is significantly faster than the maximum positioning rate.2.

Contact Now

Product advantages:1. Reduce material waste.Bent sheet metal is the process of bending metal sheets into the desired shape. It can reduce the waste of material in operations such as cutting and welding as much as possible while ensuring the quality of the workpiece. This not only reduces the cost of material procurement, but also shortens the production process and reduces the scrap rate, contributing to environmental protection.2.

Contact Now

Sheet metal parts have many advantages that make them widely used in the manufacturing and engineering fields. Here are some of the main advantages of sheet metal parts:1. Lightweight: Compared to traditional cast or forged parts, sheet metal parts are made of sheet metal, so the weight is relatively light. This gives sheet metal parts a distinct advantage in applications that require light weight, improved fuel efficiency or load capacity.2. High strength: sheet metal parts after cold processing, can enhance its strength and rigidity.

Contact Now

The benefits of customizable large-scale sheet metal processing are:1. High precision: The precision of large sheet metal can be customized, which can reach less than 0.01 mm.2. High efficiency: large sheet metal can be customized through automation equipment, high production efficiency.3. High reliability: The process of customizing large sheet metal is relatively mature and has high reliability.4. High flexibility: Large sheet metal can be customized to adapt to a variety of different specifications and shapes of products, high flexibility.5.

Contact Now

Product advantages:1. Manufacturing speed: Automation and the latest technology enable us to produce large quantities of parts in a relatively short period of time.2. Accuracy: With proper design taking into account manufacturability, bent sheet metal parts can be very precise.3. Less post-processing: Unlike welded parts, sheet metal bending require little processing after bending, aside from any additional surface finishing or hardware.4.

Contact Now

Sheet metal products have the following advantages:1. Lightweight design: Since sheet metal products are usually made of metal sheets, they are lighter than traditional solid parts. This helps reduce overall product weight, improving portability and ease of installation. It is especially important for areas such as automotive, aerospace and electronic equipment that require weight control.2. Excellent structural rigidity: Sheet metal products can form complex structures through bending, welding, etc., and have high rigidity and stability.

Contact Now

Custom large-scale sheet metal machining has many advantages:1. Strong adaptability: Customized large-scale sheet metal processing can be designed and produced according to the specific needs and requirements of customers, so as to meet specific application scenarios and requirements.2, high flexibility: Customized large-scale sheet metal processing has a high degree of flexibility, can cope with a variety of sizes, shapes, materials and requirements of the workpiece processing.3. High accuracy: Customized large-scale sheet metal processing usually has high-precision processing capabilities.

Contact Now

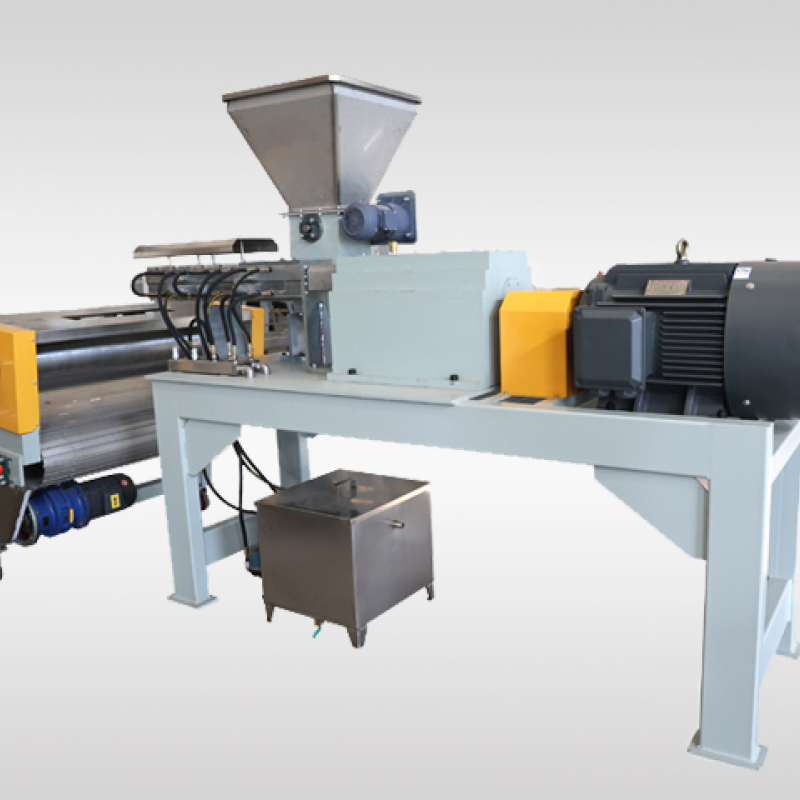

SLJ twin screw extruder has the following advantages:1. High production efficiency: SLJ twin screw extruder adopts twin screw structure, with greater extrusion capacity and higher extrusion speed. Compared with a single screw extruder, it can produce more plastic products in the same time, improving production efficiency.2. Good mixing performance: The twin screw extruder can better mix plastic raw materials through two mutually integrated rotating screws. This ensures the uniform distribution and full integration of raw materials and improves the quality of finished products.3.

Contact Now

Product Details Of Powder Coating Extruder JCJ63: Earlier than the extruder begins to paintings each time, turn the motor with the crank handle to see if the rotation is straightforward and exertions-saving. In any other case, it ought to be stored on the manner temperature for 3 to 5 minutes, till the rotation is exertions-saving, and then it's far allowed to start operation.Each time the extruder starts offevolved to paintings, the screw runs at a low speed and feeds a touch.

Contact Now

Product Details Of Powder Coating Extruder JCJ75: Before the extruder starts offevolved to work every time, flip the motor with the crank cope with to see if the rotation is handy and labor-saving. Otherwise, it ought to be saved at the procedure temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder starts offevolved to work, the screw runs at a low velocity and feeds a little.

Contact Now

Auto trunk cover plate automatic edge wrapping equipment has the following advantages:1. Improve production efficiency: Auto trunk cover plate automatic edge wrapping equipment can greatly improve production efficiency. Compared to manual assembly, automated systems can complete each step of roof assembly quickly and accurately.

Contact Now

The automobile wiring harness high-altitude spreader station conveying device is located in the upper space of the operation workbench, making full use of the space advantages of the site and avoiding site waste. High degree of intelligence, can automatically and quickly realize the loading and unloading of products between the two stations and process buffering, and will not be affected by the inconsistency of the production rhythm between the on-site production stations.

Contact Now

Auto parts tooling fixtures have the following advantages:1. High positioning accuracy: Auto parts tooling fixtures can provide accurate positioning and clamping to ensure the correct position and attitude of auto parts during processing and assembly. This ensures precision and consistency in part assembly, improving overall product quality.2. Improved productivity: By using automotive parts fixtures, operators can complete assembly and machining tasks faster and more accurately.

Contact Now

Performance Characteristics of Screw Cooling ConveyorScrew cooling conveyors play a vital role in modern industrial production. Their unique advantages lie not only in their cooling efficiency, but also in their comprehensive performance and design features.First of all, the spiral cooling conveyor stands out for its excellent cooling efficiency.

Contact Now

Performance characteristics of cooling tunnel conveyorThe cooling roller used in this cooling tunnel conveyor is undoubtedly an outstanding representative of technological innovation in the industry. It cleverly adopts the design of double-layer chrome-plated plates, which not only makes the cooling rolls look more exquisite in appearance, but also ensures their solid and durable quality in substance.

Contact Now

The design of the dry powder mixer's barrel is ingenious, with every detail carefully polished to ensure that the structure is tightly and securely connected without any unnecessary gaps. This design not only greatly enhances the stability and safety of the cylinder during transportation, but also maintains its excellent performance in long-term use.It is worth mentioning that the loading and unloading design of the machine is very innovative.

Contact Now

Due to the specific shape and cross-section characteristics of special-shaped steel profiles, it has the following advantages and advantages:1. Excellent strength and stability: The special shape design of special-shaped steel profile makes its load-bearing capacity and stiffness have been improved, so it can withstand greater loads and pressures in various engineering applications.2.

Contact Now

Single screw reciprocating extruder has the following advantages:1. Efficient production: single screw reciprocating extruder adopts reciprocating motion design, through the reciprocating extrusion action, can achieve high-speed and efficient production of plastic products. Compared to traditional single-screw extruders, reciprocating extruders can produce more product in the same amount of time.2. Energy saving: The design of the single-screw reciprocating extruder makes the use of energy more efficient.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Special-shaped steel pipe has the following advantages:1. High strength: Compared with ordinary steel, special-shaped steel pipe has higher strength. This allows it to withstand greater loads and stresses, providing more reliable structural support.2. Excellent plasticity: Special-shaped steel pipe has good plasticity and can be processed and formed to meet different design needs. This makes it more flexible and adaptable in the manufacture and installation of complex structures.3.

Contact Now

Hydraulic station supporting silent room is a specially designed soundproof room used to deal with noise problems on industrial assembly lines. It has the following advantages:1. Reduce noise interference: hydraulic station equipment usually produces a high noise level, and the silent room uses soundproof materials and structural design, which can effectively absorb, isolate and reduce the spread of noise. This can reduce noise interference to the surrounding environment and staff, providing a relatively quiet working environment.2.

Contact Now