Vacuum adsorption gluing mold has the following advantages:1. Uniform gluing pressure: The vacuum adsorption mold can achieve uniform gluing pressure on thin plates or thin materials through uniform air pressure distribution. This helps reduce deformation and warping during the gluing process, allowing for more accurate size and shape of the glued parts.2. High-quality adsorption effect: The vacuum system provides strong adsorption, which firmly adsorbs thin plates or thin materials to the mold surface.

Contact Now

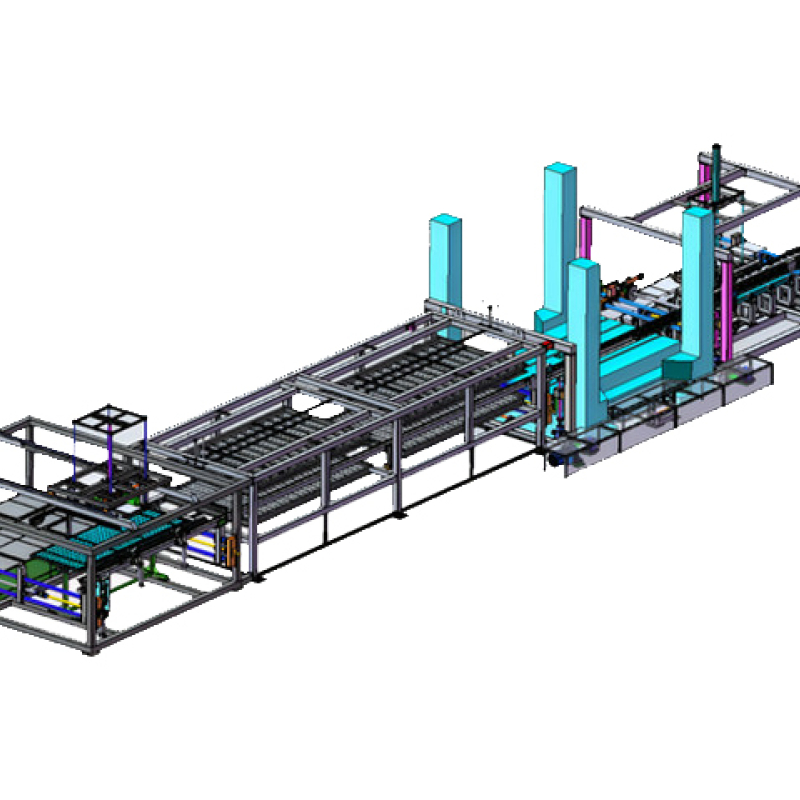

The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Car roof dry automatic molding line mainly includes: substrate loader, conveying system (including girder lifting and width adjustment system), two-stage heating and drying furnace, auxiliary material table, mold centering device, mold changing car, printer table, work Steps and safety protection devices, etc.skills requirement:1. The largest substrate and fabric size: 2950×1800mm.2. The production cycle meets the requirement of 45-60 seconds/piece.3. The horizontal height of substrate transmission: 1320mm.4.

Contact Now

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

Product advantages of machining fixturing:1. Assembly Nest and Tools.2. CMM Holding Fixtures.3. Photometric Holding Fixtures.4. Custom Vacuum Pads and Machine Seals.5. ESD Dissipative 3D Printed Nest and Tools.6. Validation and Testing Fixtures.7. In-Process Quality Check Tools.8. Poka-Yoke.9. T-Slot Equipment Design and Assembly (8020).10. Machine Guards.11. Organization and 5S equipment.

Contact Now

Product Details:When the powder machine is working, the materials entering the grinding area of the grinding disc are crushed by the impact column, and under the action of the suction of the induced draft fan, they go up and down along the two sides of the return circle and enter the separation area to be sprayed out from the material outlet through the fan separator. Due to the high-speed rotation of the fan blade separator, the centrifugal force generated hinders the passage of materials.

Contact Now

Advantages of sheet metal finishing:1. Flexibility: Sheet metal finishing can flexibly customize and manufacture parts and products of various shapes and sizes according to customer needs and design requirements.2. High precision: Advanced sheet metal finishing equipment and technology can achieve high-precision cutting, bending and punching operations to ensure product quality.3. Wide range of materials: Sheet metal finishing can be applied to a variety of metal materials, such as stainless steel, aluminum alloy, carbon steel, etc., to meet the needs of different application fields.4.

Contact Now

Sheet metal panels have the following advantages:1. High shape accuracy: Sheet metal panels can be processed by CNC equipment, which can achieve high-precision shape requirements.2. Wide selection of materials: It can process a variety of metal materials, such as stainless steel, aluminum alloy, copper alloy, etc. Different materials can be selected according to needs.3. Flexible process: Sheet metal panels can use a variety of processes, such as bending, stamping, shearing, etc. Different processes can be selected according to needs.4.

Contact Now

1. Fast processing speed.The most significant advantage of sheet metal processing technology is that the cutting speed is fast and is not limited by the number of processes. But it is more suitable in the production process, because it does not waste time changing tools and effectively increases the processing speed; to a certain extent, its processing speed is significantly faster than the maximum positioning rate.2.

Contact Now

Toyota Eifang RAV4 line speed transmission line has the following advantages:1. Improve production efficiency: The line speed transmission line uses an automated way to transmit the vehicle or vehicle parts from one workstation to another in an uninterrupted state, reducing the pause time in the production process and improving production efficiency.2. Quality control: Through the use of line speed transmission lines, Toyota can achieve strict control over the production process to ensure that each vehicle is assembled and inspected in accordance with standard procedures.

Contact Now

Product Details:1. Because stainless metal has correct corrosion resistance, environmental protection, dustproof, and antistatic, it can make structural aspects preserve the integrity of engineering design.2. The stainless metal workbench adopts stainless metal structure, in most cases adopts stainless metal rectangular tube, stainless metal plate, and the foot of the workbench can be adjusted up and down with a foot cup to adapt to uneven ground.3.

Contact Now

Product advantages:1. It is handy to deform, so that quite a number types of factors can be manufactured with easy processing technology.2. Sheet metallic structural components are mild in weight.3. The quantity of processing is small. Due to the excessive floor fantastic of the bending sheet metal and the small dimensional tolerance in the thickness direction, the plate floor does no longer want to be processed.4. It is convenient to reduce and weld, and can manufacture giant and complicated components.5. The structure is standardized, which is handy for automated processing.

Contact Now

1. Composition of auto body-in-white welding fixture.Welding fixture is an auxiliary means in the production of products. It is a general term for the process equipment used for assembly and welding, including the guiding device for guiding the welding torch or the workpiece, which quickly and accurately locates and fixes the workpiece at the desired position. Welding fixture is an indispensable auxiliary device for metal structure welding and an important part of the welding process.

Contact Now

Special-shaped steel pipe has the following advantages:1. High strength: Compared with ordinary steel, special-shaped steel pipe has higher strength. This allows it to withstand greater loads and stresses, providing more reliable structural support.2. Excellent plasticity: Special-shaped steel pipe has good plasticity and can be processed and formed to meet different design needs. This makes it more flexible and adaptable in the manufacture and installation of complex structures.3.

Contact Now

Sheet metal processing products have the following advantages:1. High strength: Metal frame are usually made of metal materials, which have high strength and rigidity and can withstand certain loads and pressures.2. High precision: Metal frame are usually processed using CNC processing equipment, which has high processing precision and accuracy and can meet high-precision manufacturing needs.3. Good corrosion resistance: Metal frame are usually made of stainless steel, aluminum alloy and other materials.

Contact Now

Automotive assembly fixtures play an important role in the manufacturing and production process. Their main functions include:1. Positioning and clamping: The workpiece fixture can fix and clamp the workpiece to maintain its correct position and attitude. They provide accurate positioning, ensuring the exact location of workpieces during machining, assembly and other operations.2. Increased productivity: By using fixtures, operators can complete machining, assembly and other production tasks more quickly and accurately.

Contact Now

The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Product advantages:1. Reduce material waste.Bent sheet metal is the process of bending metal sheets into the desired shape. It can reduce the waste of material in operations such as cutting and welding as much as possible while ensuring the quality of the workpiece. This not only reduces the cost of material procurement, but also shortens the production process and reduces the scrap rate, contributing to environmental protection.2.

Contact Now

Product advantages:Compared with the production and processing of forgings and castings, hand metal bender has the advantages of light weight, saving metal materials, simple processing technology, reducing production costs, and saving production expenses. Most of the hand metal bender that has been welded have low processing accuracy and large welding deformation.

Contact Now

Special-shaped steel is a special shape of steel that has many advantages. Here are some common advantages of special-shaped steel:1. Structural strength: Special-shaped steel can be designed and manufactured according to needs, with excellent structural strength and rigidity. They are precisely calculated and optimized to withstand a variety of loads and pressures and maintain structural stability.2. Good bearing capacity: Due to its special cross-section shape, special-shaped steel performs well in bearing weight and pressure.

Contact Now

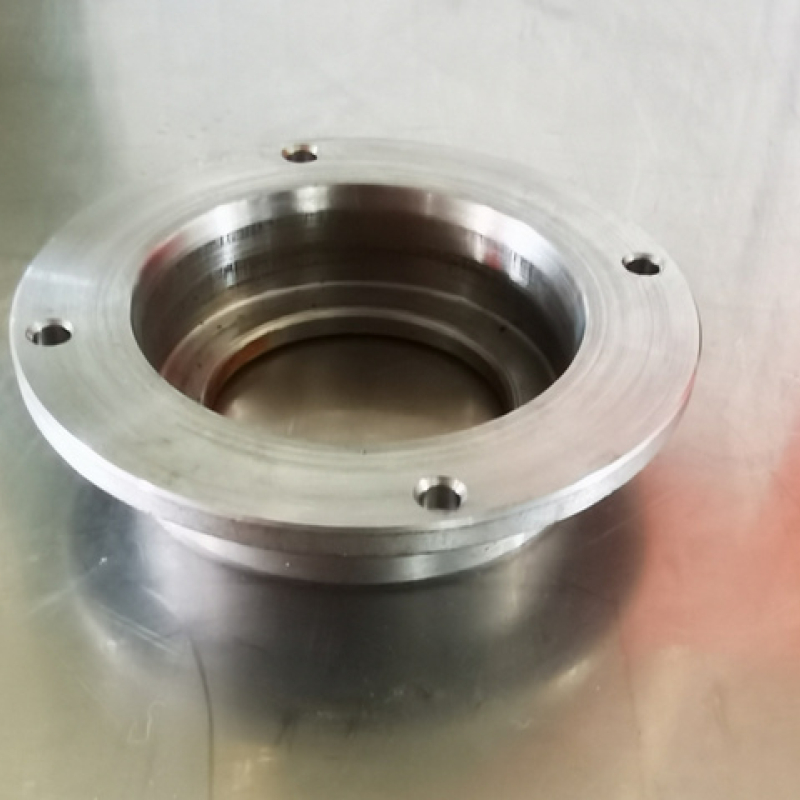

Product advantages:1. Can improve the production yield rate of enterprises.For manufacturing companies, whether they produce equipment products themselves or use equipment to produce specific products, if machined parts are integrated, the product yield rate will be much higher than that of general equipment. This is mainly due to the good reputation of machined parts. With higher precision, the equipment composed of these parts will naturally have higher precision, and the quality of the products produced will definitely be more guaranteed.2.

Contact Now

Special steel section has a variety of advantages, these advantages can be summarized as follows: 1. Special steel section has excellent structural stability. Due to the shape characteristics of its cross section, special steel section can show excellent bending resistance and toughness, thereby effectively improving stability and safety.2. The weight of special steel section is relatively light.

Contact Now

Products advantages:1. Lightweight: Compared with solid metal components, metal pallets are composed of thin plates and therefore have a lighter weight.2. Strength and stiffness: Processing metal plates through bending, welding and other processes can enhance the structural strength and stiffness of the product.3. Beautiful appearance: Metal pallet can be polished, sprayed and other surface treatments to give them a good appearance.4.

Contact Now