The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Harness clamp is a tool used to test and assemble electronic harness. Its functions mainly include the following aspects:1. Test function: Harness clamp can be used to test the electrical connectivity and functionality of harness. It is able to check whether the wire connection inside the harness is good by connecting the power supply and the test instrument, and verify that the harness can work properly when running.2.

Contact Now

Fix wiring harness fixtures have the following advantages:1. Improve production efficiency: Wire harness fixtures can automatically test and verify wire harnesses, reducing the time and effort required for manual operations. It can quickly connect and disconnect wire harnesses, effectively improving the efficiency of the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure that each wire harness is tested and verified according to the same standards, thus ensuring consistency and quality control.

Contact Now

Harness holding device is a device used to fix and protect electrical wiring harness, it has the following advantages:1. Provide reliable fixation and protection: The wiring harness fixing device is designed to firmly fix the wiring harness to prevent it from loosening, shaking or external impact. This helps keep the wiring harness neat and compact, avoids interference or wear between wires, and provides reliable electrical connections and transmission. At the same time, they also provide protection from external environmental damage such as vibration, temperature changes, chemicals, etc.2.

Contact Now

The following are the advantages of the wiring harness fixture:1. Easy to use: wiring harness fixture can be quickly and easily installed and adjusted without any professional tools. Simply place the wires and cables into clamps and then clamp them manually or automatically.2. Flexibility: wiring harness fixture has a high degree of flexibility, suitable for a variety of different types of wire and cable. The clamps can be adjusted or moved as needed to suit different applications and wiring needs.3.

Contact Now

Characteristics of wire net storage rack:1. Unique structure: It is made of carbon metal chrome-plated mesh and pillars. Its special structure shape is clever in design, handy to load and unload, smooth and bright, and the robust carbon metal chrome-plated mesh can promote air circulation and decrease dirt accumulation. The open graph makes storage seen at a glance.2. Flexible: There is a groove circle for each and every inch of the pillar, and the top of the mesh can be adjusted at will (increase or minimize per inch).

Contact Now

The automobile wiring harness high-altitude spreader station conveying device is located in the upper space of the operation workbench, making full use of the space advantages of the site and avoiding site waste. High degree of intelligence, can automatically and quickly realize the loading and unloading of products between the two stations and process buffering, and will not be affected by the inconsistency of the production rhythm between the on-site production stations.

Contact Now

The Cadillac XT5 Line has the following advantages:1. Improve production efficiency: The use of automation technology can achieve continuous and efficient vehicle or parts transmission, reducing the pause time in the production process and improving production efficiency. This helps speed up production and increase output.2. Quality control: The use of wire speed transmission line can achieve strict control of the production process. Each vehicle is inspected and tested as it passes through the various workstations to ensure accurate quality standards are met.

Contact Now

Product advantages:1. Manufacturing speed: Automation and the latest technology enable us to produce large quantities of parts in a relatively short period of time.2. Accuracy: With proper design taking into account manufacturability, bent sheet metal parts can be very precise.3. Less post-processing: Unlike welded parts, sheet metal bending require little processing after bending, aside from any additional surface finishing or hardware.4.

Contact Now

Product advantages:1. Reduce material waste.Bent sheet metal is the process of bending metal sheets into the desired shape. It can reduce the waste of material in operations such as cutting and welding as much as possible while ensuring the quality of the workpiece. This not only reduces the cost of material procurement, but also shortens the production process and reduces the scrap rate, contributing to environmental protection.2.

Contact Now

Product Details:The biggest advantage of sheet metal processing products is that they are suitable for small batch and multi-variety production. Stamping processing is a processing method of plastic processing and is suitable for mass production of multiple parts of the same shape.

Contact Now

1. Fast processing speed.The most significant advantage of sheet metal processing technology is that the cutting speed is fast and is not limited by the number of processes. But it is more suitable in the production process, because it does not waste time changing tools and effectively increases the processing speed; to a certain extent, its processing speed is significantly faster than the maximum positioning rate.2.

Contact Now

Product advantages:1. Lightweight:Sheet stamping is typically lighter than traditional metal products, making them more practical in many applications. For example, in the automotive manufacturing industry, the use of sheet metal products can reduce the weight of vehicles, thereby improving fuel effciency and performance.2. Corrosion resistance: Sheet metal products often have a high level of corrosion resistance, which makes them more durable in many applications. 3. Plasticity: Sheet metal products have high plasticity, which allows them to be made into various shapes and sizes.

Contact Now

Bending aluminium sheet offers several advantages. 1. It enables highly precise bending angles and shapes, ensuring part accuracy and consistency. 2. Sheet metal bending processing has high production efficiency and can quickly complete large-volume production tasks. 3. Because the bending process does not require the use of welds or connections, it reduces part weight and cost. 4. Sheet metal materials have good strength and corrosion resistance and can meet various application requirements.

Contact Now

Product advantages:Compared with the production and processing of forgings and castings, hand metal bender has the advantages of light weight, saving metal materials, simple processing technology, reducing production costs, and saving production expenses. Most of the hand metal bender that has been welded have low processing accuracy and large welding deformation.

Contact Now

Bending angle has the following advantages:1. Flexibility: Bending sheet metal can achieve various complex shapes and angles to adapt to different product needs. By adjusting the clamps and molds on the folding bed, the angle and radius can be flexibly adjusted, making the bending sheet metal suitable for various design requirements.2. High precision: Bending sheet metal can achieve higher precision requirements.

Contact Now

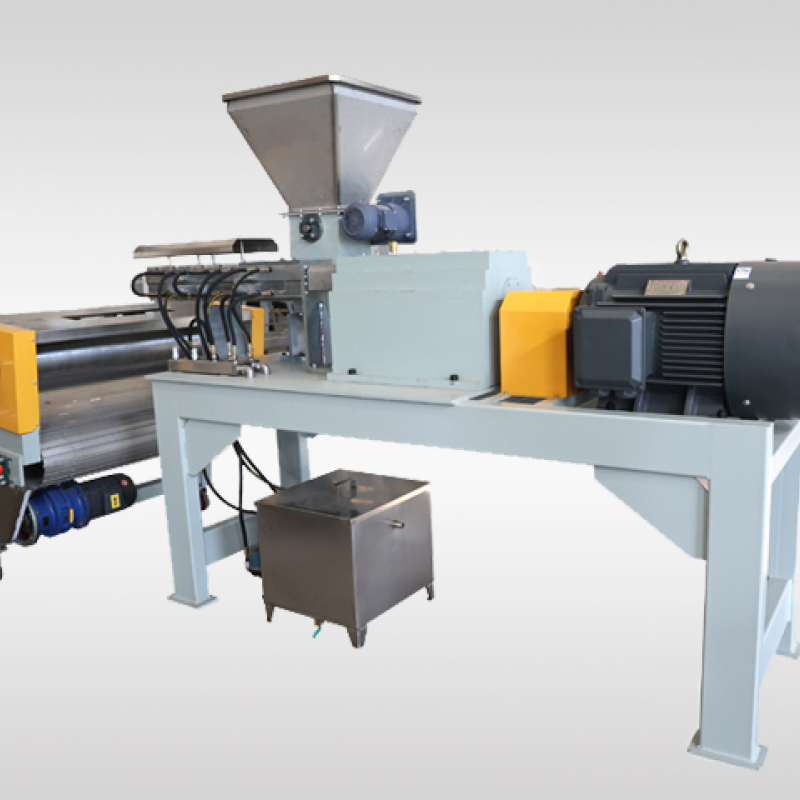

Single screw reciprocating extruder has the following advantages:1. Efficient production: single screw reciprocating extruder adopts reciprocating motion design, through the reciprocating extrusion action, can achieve high-speed and efficient production of plastic products. Compared to traditional single-screw extruders, reciprocating extruders can produce more product in the same amount of time.2. Energy saving: The design of the single-screw reciprocating extruder makes the use of energy more efficient.

Contact Now

SLJ twin screw extruder has the following advantages:1. High production efficiency: SLJ twin screw extruder adopts twin screw structure, with greater extrusion capacity and higher extrusion speed. Compared with a single screw extruder, it can produce more plastic products in the same time, improving production efficiency.2. Good mixing performance: The twin screw extruder can better mix plastic raw materials through two mutually integrated rotating screws. This ensures the uniform distribution and full integration of raw materials and improves the quality of finished products.3.

Contact Now

Extruder machine is a widely used equipment in industrial production, especially in the processing of plastics, rubber and other materials play an indispensable role. This extruder adopts the design of single-screw upper feeding, which not only improves the feeding efficiency, but also ensures the uniformity of feeding.

Contact Now

Product Details Of Powder Coating Extruder JCJ75: Before the extruder starts offevolved to work every time, flip the motor with the crank cope with to see if the rotation is handy and labor-saving. Otherwise, it ought to be saved at the procedure temperature for three to 5 minutes, till the rotation is labor-saving, and then it is allowed to begin operation.Every time the extruder starts offevolved to work, the screw runs at a low velocity and feeds a little.

Contact Now

Features:1.High welding precision and steadiness of spare parts.The jigs welding fixtures are used for constant spare parts. It ensures the right relative function at some point of the manufacturing process. Workpeice deformation can be prevented. Especially in mass production, the fixtures warranty exceptional welding quality.2.High welding precision of the widely wide-spread automobile body, handy operation.Spare components of clamping mechanism makes use of materials of equal mechanical performance.

Contact Now

The silent room can be customized is a workshop for testing equipment, which can be a mobile silent room. The silent room can be customized adopts sound absorption on four sides and the top surface, and the sound insulation method of the bottom layer makes the room achieve a low-noise environment. Its background noise value in the soundproof room is less than 35-40dB. In addition to the sound absorption system, the soundproof room also needs to be equipped with soundproof doors, windows, ventilation systems, electrical systems, etc. according to the actual situation.

Contact Now

Auto trunk cover plate automatic edge wrapping equipment has the following advantages:1. Improve production efficiency: Auto trunk cover plate automatic edge wrapping equipment can greatly improve production efficiency. Compared to manual assembly, automated systems can complete each step of roof assembly quickly and accurately.

Contact Now