The following are the advantages of the wiring harness fixture:1. Easy to use: wiring harness fixture can be quickly and easily installed and adjusted without any professional tools. Simply place the wires and cables into clamps and then clamp them manually or automatically.2. Flexibility: wiring harness fixture has a high degree of flexibility, suitable for a variety of different types of wire and cable. The clamps can be adjusted or moved as needed to suit different applications and wiring needs.3.

Contact Now

Harness holding device is a device used to fix and protect electrical wiring harness, it has the following advantages:1. Provide reliable fixation and protection: The wiring harness fixing device is designed to firmly fix the wiring harness to prevent it from loosening, shaking or external impact. This helps keep the wiring harness neat and compact, avoids interference or wear between wires, and provides reliable electrical connections and transmission. At the same time, they also provide protection from external environmental damage such as vibration, temperature changes, chemicals, etc.2.

Contact Now

Fix wiring harness fixtures have the following advantages:1. Improve production efficiency: Wire harness fixtures can automatically test and verify wire harnesses, reducing the time and effort required for manual operations. It can quickly connect and disconnect wire harnesses, effectively improving the efficiency of the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure that each wire harness is tested and verified according to the same standards, thus ensuring consistency and quality control.

Contact Now

Wire harness fixtures provide several advantages during harness manufacturing and testing:1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness.

Contact Now

Harness clamp is a tool used to test and assemble electronic harness. Its functions mainly include the following aspects:1. Test function: Harness clamp can be used to test the electrical connectivity and functionality of harness. It is able to check whether the wire connection inside the harness is good by connecting the power supply and the test instrument, and verify that the harness can work properly when running.2.

Contact Now

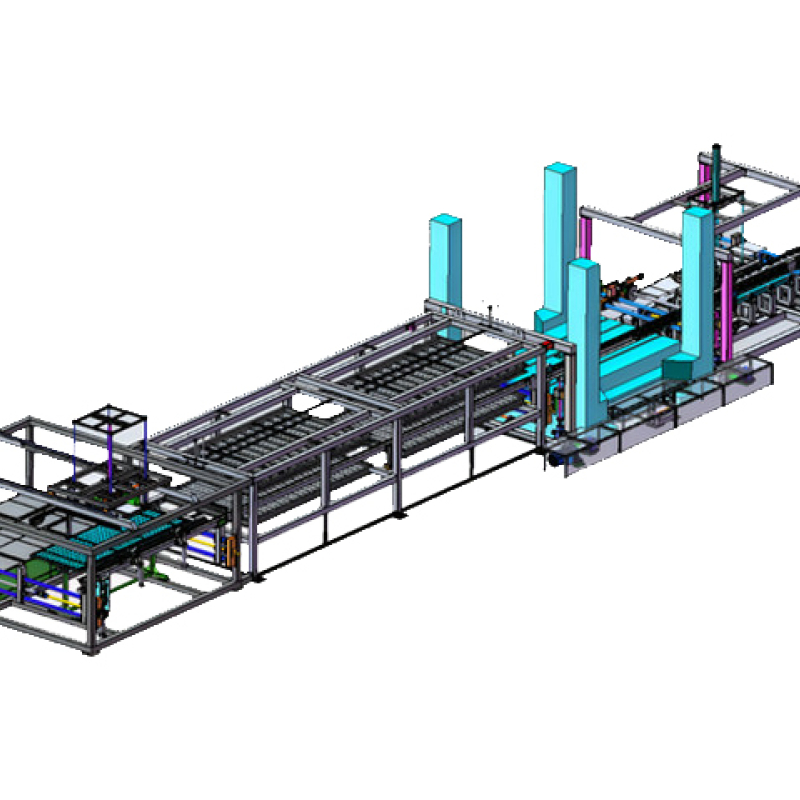

The automobile wiring harness high-altitude spreader station conveying device is located in the upper space of the operation workbench, making full use of the space advantages of the site and avoiding site waste. High degree of intelligence, can automatically and quickly realize the loading and unloading of products between the two stations and process buffering, and will not be affected by the inconsistency of the production rhythm between the on-site production stations.

Contact Now

The predominant characteristic of the tooling hole fixture is to restore and hit upon the function of the object. Compared with the jig, it has an extra positioning function. The jigs that are frequently considered will use geometric restrictions to role the object, so like positioning blocks, positioning Pins regularly have a bevel format to guide the object into a fantastically small area and restriction the function of the object.

Contact Now

The advantages of wire harness processing equipment:1. Improve processing accuracy: The wire harness processing equipment can fix the wire harness and provide precise positioning, thereby reducing manual operation errors and improving processing accuracy.2. Improve production efficiency: Wire harness processing equipment can make the wire harness processing process more efficient, reduce manual operation time and labor intensity, and improve production efficiency.3.

Contact Now

Welding fixture is an auxiliary device wanted in the manner of physique welding. The workpiece can be precisely located on the vehicle manufacturing line thru the welding fixture, and the welding computer can be guided to the role for welding via the fixture. In the system of physique welding, the vehicle physique is made of steel materials, and the fixture is an imperative phase of metallic welding.

Contact Now

1. Composition of auto body-in-white welding fixture.Welding fixture is an auxiliary means in the production of products. It is a general term for the process equipment used for assembly and welding, including the guiding device for guiding the welding torch or the workpiece, which quickly and accurately locates and fixes the workpiece at the desired position. Welding fixture is an indispensable auxiliary device for metal structure welding and an important part of the welding process.

Contact Now

Fixtures have been extensively used earlier than the industrial age, inclusive of mechanical fixtures, woodworking fixtures, welding fixtures, rings fixtures, and different fields.

Contact Now

Automotive assembly fixtures play an important role in the manufacturing and production process. Their main functions include:1. Positioning and clamping: The workpiece fixture can fix and clamp the workpiece to maintain its correct position and attitude. They provide accurate positioning, ensuring the exact location of workpieces during machining, assembly and other operations.2. Increased productivity: By using fixtures, operators can complete machining, assembly and other production tasks more quickly and accurately.

Contact Now

Auto parts tooling fixtures have the following advantages:1. High positioning accuracy: Auto parts tooling fixtures can provide accurate positioning and clamping to ensure the correct position and attitude of auto parts during processing and assembly. This ensures precision and consistency in part assembly, improving overall product quality.2. Improved productivity: By using automotive parts fixtures, operators can complete assembly and machining tasks faster and more accurately.

Contact Now

Product advantages:1. Strong bearing capacity: After design and calculation, the connecting bearing can bear the load capacity of the building structure, including gravity load, horizontal load and shear force. They can effectively transfer and disperse loads, ensuring the stability and safety of the structure.2. Shock absorption and energy absorption capabilities: The connection supports can have shock absorption and energy absorption functions to reduce the impact of external factors such as earthquakes and wind loads on the structure.

Contact Now

Vacuum adsorption gluing mold has the following advantages:1. Uniform gluing pressure: The vacuum adsorption mold can achieve uniform gluing pressure on thin plates or thin materials through uniform air pressure distribution. This helps reduce deformation and warping during the gluing process, allowing for more accurate size and shape of the glued parts.2. High-quality adsorption effect: The vacuum system provides strong adsorption, which firmly adsorbs thin plates or thin materials to the mold surface.

Contact Now

Dry automatic forming production line for car roof has the following advantages:1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality.

Contact Now

Performance Characteristics of Screw Cooling ConveyorScrew cooling conveyors play a vital role in modern industrial production. Their unique advantages lie not only in their cooling efficiency, but also in their comprehensive performance and design features.First of all, the spiral cooling conveyor stands out for its excellent cooling efficiency.

Contact Now

Mobile home silent room has the following advantage:1. Very high noise reduction effect: The fixed silent room adopts professional sound insulation materials and sound insulation structure design, which can effectively reduce the transmission and reflection of external noise, and achieve a very high level of noise reduction effect. This can effectively protect the quiet and comfortable indoor environment, which is especially important for high demand and low noise sensitivity working environment.2.

Contact Now

Tool holder in the factory have the following advantages:1. Improve work efficiency: Tool holder can make items easier to find and access, thereby improving work efficiency.2. Keep things neat and orderly: Tool holder can store items in categories and keep the work area tidy and orderly.3. Avoid loss and damage of items: The storage rack can provide a fixed storage location for items to avoid loss and damage of items.4. Save space: The storage rack can store items vertically, saving space and making the factory more spacious and comfortable.5.

Contact Now

The silent room can be customized is a workshop for testing equipment, which can be a mobile silent room. The silent room can be customized adopts sound absorption on four sides and the top surface, and the sound insulation method of the bottom layer makes the room achieve a low-noise environment. Its background noise value in the soundproof room is less than 35-40dB. In addition to the sound absorption system, the soundproof room also needs to be equipped with soundproof doors, windows, ventilation systems, electrical systems, etc. according to the actual situation.

Contact Now

Our advantages:1. Independent design and development, processing and production, no other middlemen, low production cost, excellent product price.2. It can be customized according to the customer's product production needs, and can meet different customer needs.

Contact Now

The automobile roof dry automatic molding lines offer many advantages:1. Efficient production: The dry automatic molding line for automobile roofs can achieve efficient production speed and continuous production. Compared with manual operations, automated equipment can complete production steps such as molding and cooling faster, improving production efficiency.2. Consistent product quality: The automobile roof dry automatic molding line can ensure the consistency and quality stability of each ceiling by precisely controlling temperature, pressure and process parameters.

Contact Now

Product DetailsCooling belt YPJ800 is driven through a frequency conversion motor, and the sprocket is pushed via a reducer. the discount gadget drives the nodal stainless steel conveyor belt, the pill roller, and the crushing curler to move synchronously.The material extruded by the extruder falls vertically among the two rollers, and as the curler rotates, the new material is brought into the gap among the rollers for extrusion.

Contact Now

Advantages of cooling conveyor belt include:1. High production efficiency: The cooling conveyor belt can quickly press powder or granular raw materials into solid tablets, improving production efficiency.2. Good product quality: The cooling conveyor belt can adjust the pressing parameters according to different needs and material characteristics to obtain the required product quality and output.3. Simple operation: The operation of the cooling conveyor belt is relatively simple. You only need to set the parameters and put in the raw materials as required.4.

Contact Now