Car Roof Dry Automatic Molding Line

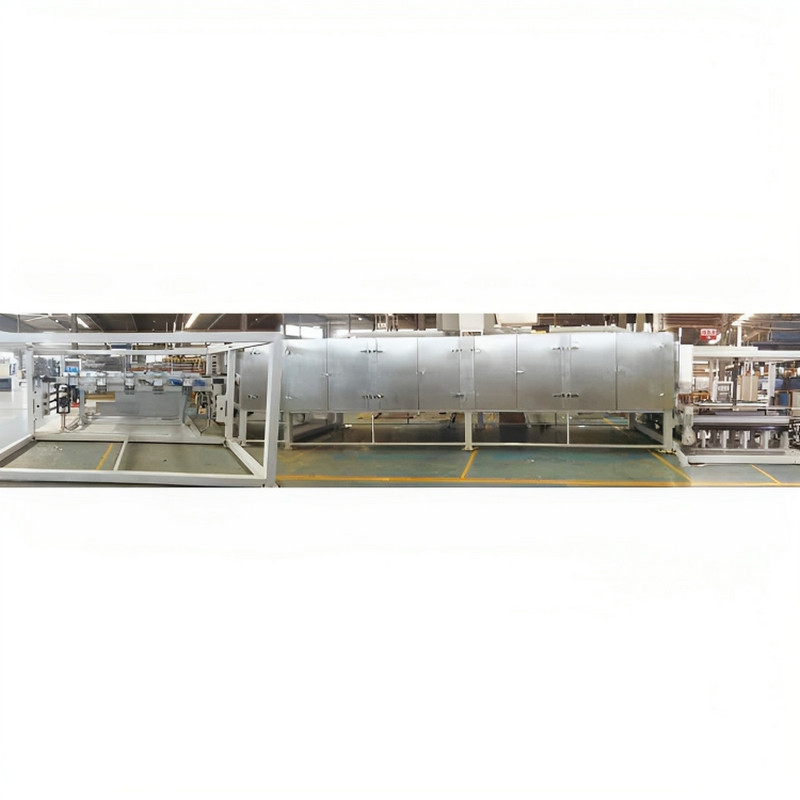

The car roof dry automatic molding line is a fully automatic production line. After heating the substrate board for the roof at more than 200 degrees, car roof dry automatic molding line is transported to the forming mold of the press and then automatically compounded and superimposed with the roof fabric. After the 200-ton press is molded Automatic mold release, can produce automotive interior products such as automotive roofs, automotive sunroof sunshades, etc. Fully automatic production, high degree of automation saves manpower, high production efficiency, high yield, can reduce production costs and improve product market competitiveness.

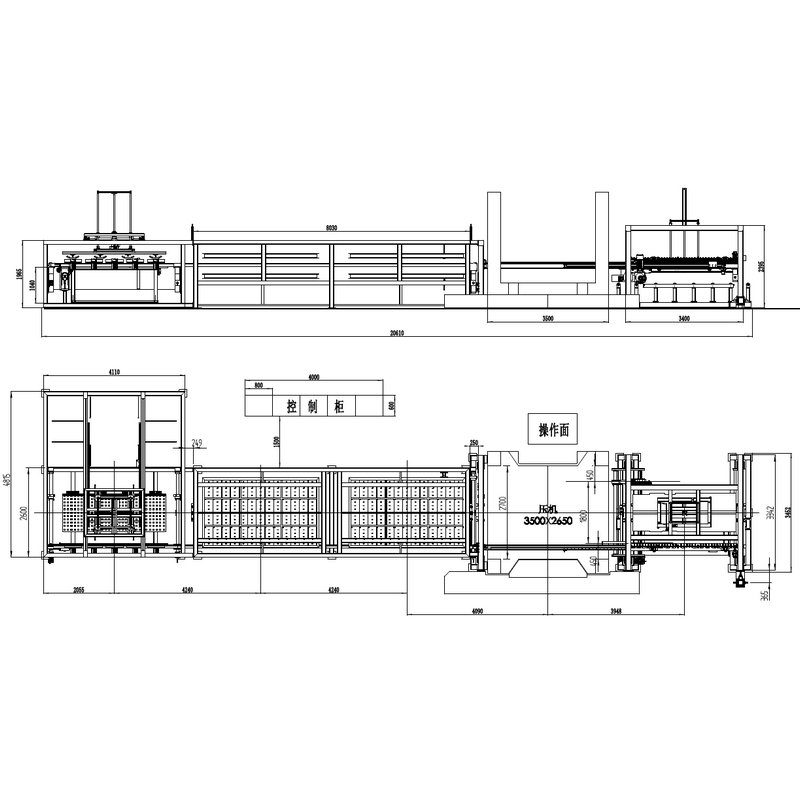

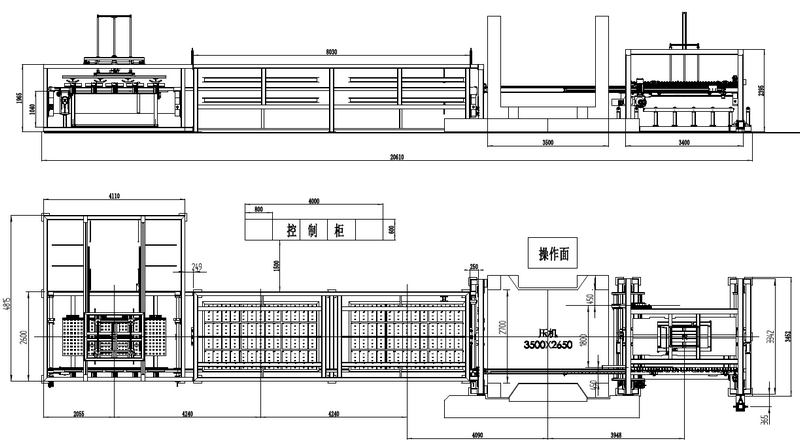

Car roof dry automatic molding line mainly includes: substrate loader, conveying system (including girder lifting and width adjustment system), two-stage heating and drying furnace, auxiliary material table, mold centering device, mold changing car, printer table, work Steps and safety protection devices, etc.

skills requirement:

1. The largest substrate and fabric size: 2950×1800mm.

2. The production cycle meets the requirement of 45-60 seconds/piece.

3. The horizontal height of substrate transmission: 1320mm.

4. Two-stage heating and drying furnace.

a) Effective heating size: 3250×1900mm.

b) Arrangement of the heating plate: the distance between the upper heating tile and the substrate is 150mm, and the distance between the lower heating tile and the substrate is 250mm.

c) HFS/1 is used for the heating tile, T-HFS/1 is used for the heating tile with thermocouple, the power of the heating tile is 400W, and the brand is Elstein.

d) Each heating plate is divided into 14 zones (the heating area can be controlled for products of different sizes, saving energy consumption).

Submitted successfully

We will contact you as soon as possible