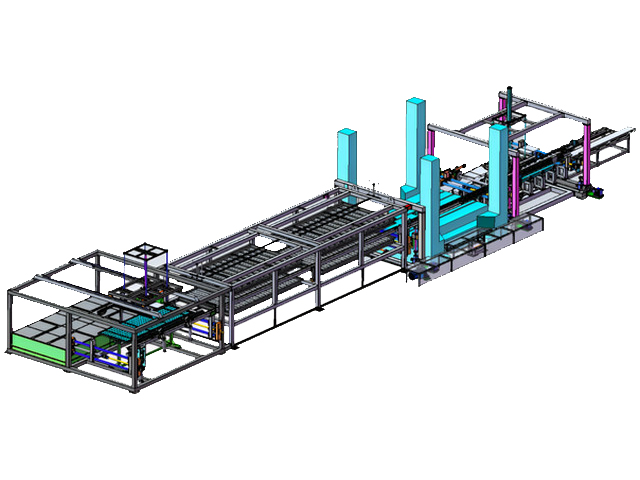

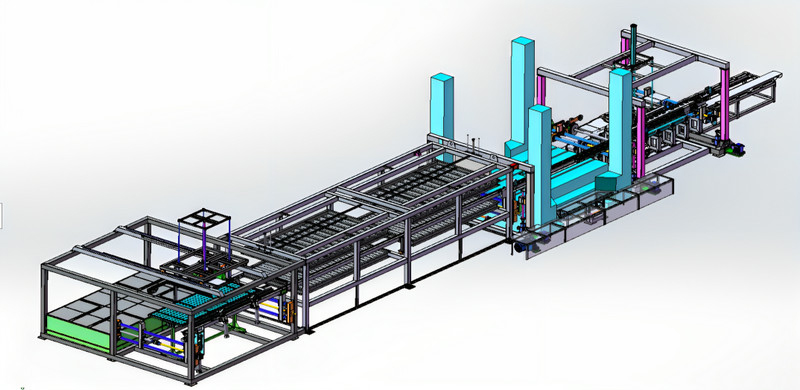

Dry Automatic Forming Production Line For Car Roof

Dry automatic forming production line for car roof is a kind of production line widely used in automobile manufacturing plants for manufacturing automotive ceiling parts. The roof is the upper covering part of the car body, usually composed of multi-layer composite materials, which has the role of protecting the interior space and providing sound insulation and heat insulation functions.

Dry automatic molding is a method of manufacturing composite materials. In the automotive roof dry automatic molding line, first of all, according to the design requirements, the fiber reinforced material (such as glass fiber or carbon fiber) is pre-treated (such as cutting, placing) in the mold for pre-positioning. The mold is then closed and a pre-positioned fiber-reinforced material is injected into the mold with a resin (such as polyester or epoxy) to form a composite ceiling component. Finally, the composite ceiling is cured and molded in a mold, and at the right temperature and pressure, the resin will cure to form a strong ceiling structure.

Dry automatic forming production line for car roof has the following advantages:

1. Efficient production: dry automatic molding line adopts automatic equipment and system, which can achieve continuous and efficient production process. Compared with manual manufacturing, it greatly improves the production efficiency and speeds up the manufacturing speed of ceiling components.

2. Consistent quality: Through automatic control and precise production process, the dry automatic molding line can produce ceiling parts with consistent quality. This ensures that each ceiling is consistent in size and quality, reducing variability in manufacturing and increasing the quality level of the overall product.

3. Accurate size: The dry automatic molding line adopts the mold and automatic positioning system, which can accurately control the size and shape of the ceiling components. This helps to ensure a perfect fit between the roof and other body components, improving the assembly quality of the vehicle.

4. Save materials: The dry molding process can accurately control the amount of resin and fiber reinforced materials, and minimize the waste of materials. This helps improve production efficiency while also reducing cost and waste of resources.

5. Good appearance and texture: The ceiling parts made by dry automatic molding line have smooth and neat surface texture, no obvious bubbles or defects. This enhances the overall look and feel of the car's roof, enhancing the vehicle's brand image and ride comfort.

Submitted successfully

We will contact you as soon as possible