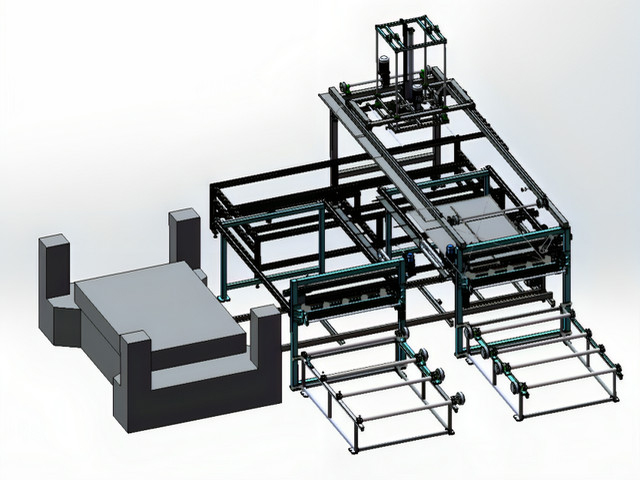

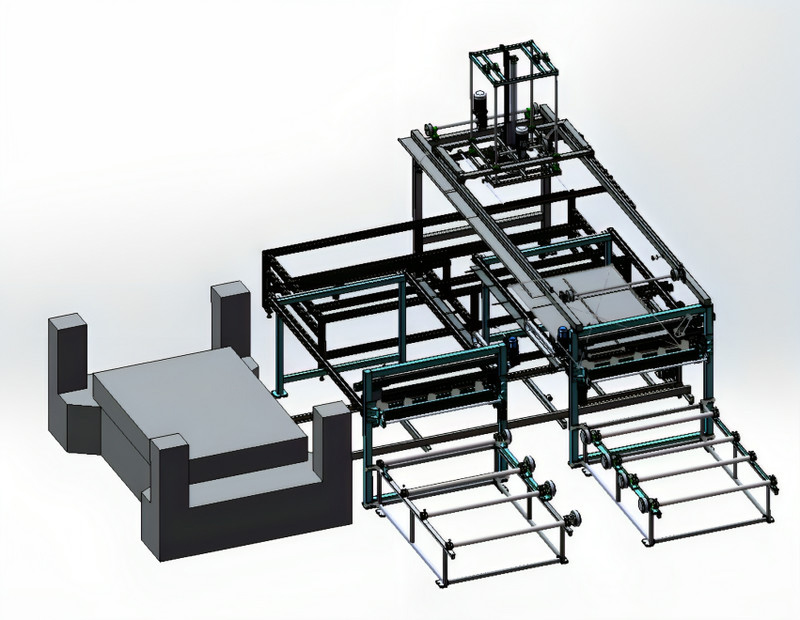

Auto Roof Multi-Layer Automatic Slicing Compound Feeding Machine

Auto roof multi-layer automatic slicing compound feeding machine is a kind of equipment for preparing composite materials, which is widely used in automobile manufacturing and other fields. It is an automated device for cutting fiber reinforced materials, such as carbon fiber or glass fiber, and positioning them in the appropriate position for the next step in composite fabrication.

Auto roof multi-layer automatic slicing compound feeding machine work by feeding fiber-reinforced material (usually in the form of rolls or sheets) into the machine, which is then cut into the desired shape and size by an automatic cutting system. The cut fiber reinforced material is transported to the appropriate location and is accurately placed on a mold or workbench by a positioning system for subsequent composite manufacturing processes.

Advantages of auto roof multi-layer automatic slicing compound feeding machine include:

1. Improve efficiency: Automated cutting and feeding process can greatly improve production efficiency, reduce manual operation and waste of time.

2. Accuracy and consistency: The machine can precisely cut and position the fiber reinforced material, ensuring precision and consistency in the composite manufacturing process.

3. Cost saving: The use of automatic slicing composite feeder can reduce human resource costs, improve production efficiency, reduce material waste, thereby saving manufacturing costs.

4. Wide applicability: Automatic slicing composite feeding machine can be applied to various types of composite materials and different shapes of parts manufacturing, with high flexibility and adaptability.

Submitted successfully

We will contact you as soon as possible