Jig And Fixture Design

Jig and fixture design is a tool used in the production and assembly process of auto parts. They are used to clamp, position and hold automotive parts in the correct position and attitude for operations such as machining, assembly, welding, measurement, testing and calibration.

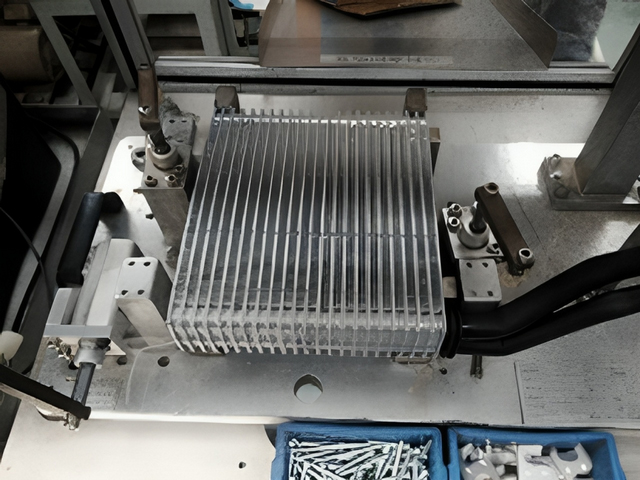

The design and manufacturing of auto parts tooling fixtures need to be customized according to the shape, size and process requirements of the specific auto parts. They can be mechanical clamps, such as clamp jaws, clamp arms, etc., or they can be pneumatic, hydraulic or electrically controlled clamping systems. The fixture usually consists of fixture bed, positioning pin, fixture block, vacuum suction cup, fixture support and other components.

The main function of the jig and fixture design is to provide precise positioning and stable clamping of auto parts to ensure the accurate position and quality of the parts during the production process. They can help improve production efficiency, reduce labor costs, and ensure product consistency and quality. At the same time, they can also provide operator safety protection and reduce risks and errors during operation.

Auto parts tooling fixtures have the following advantages:

1. High positioning accuracy: Auto parts tooling fixtures can provide accurate positioning and clamping to ensure the correct position and attitude of auto parts during processing and assembly. This ensures precision and consistency in part assembly, improving overall product quality.

2. Improved productivity: By using automotive parts fixtures, operators can complete assembly and machining tasks faster and more accurately. Fixtures can hold parts, make them stable, and provide accurate positioning, reducing adjustment and alignment time, thereby increasing production line efficiency.

3. Reduce manual errors: Jig and fixture design provide reliable positioning and clamping, reducing errors caused by human factors during the assembly process. Fixtures can ensure that parts are in the correct position, reduce errors and defects during assembly, and improve assembly quality.

4. Improved safety: Auto parts fixtures are able to secure and clamp heavy or complex parts, providing operator safety. Clamps can reduce risks during operation, prevent parts from sliding, tilting or accidentally falling off, and ensure operator safety.

5. Reusable: Auto parts tooling fixtures are often reusable and can be used across multiple production runs. They can be adjusted and adapted to different part sizes and shapes as needed, providing long-term use value. This also helps reduce production costs.

Submitted successfully

We will contact you as soon as possible