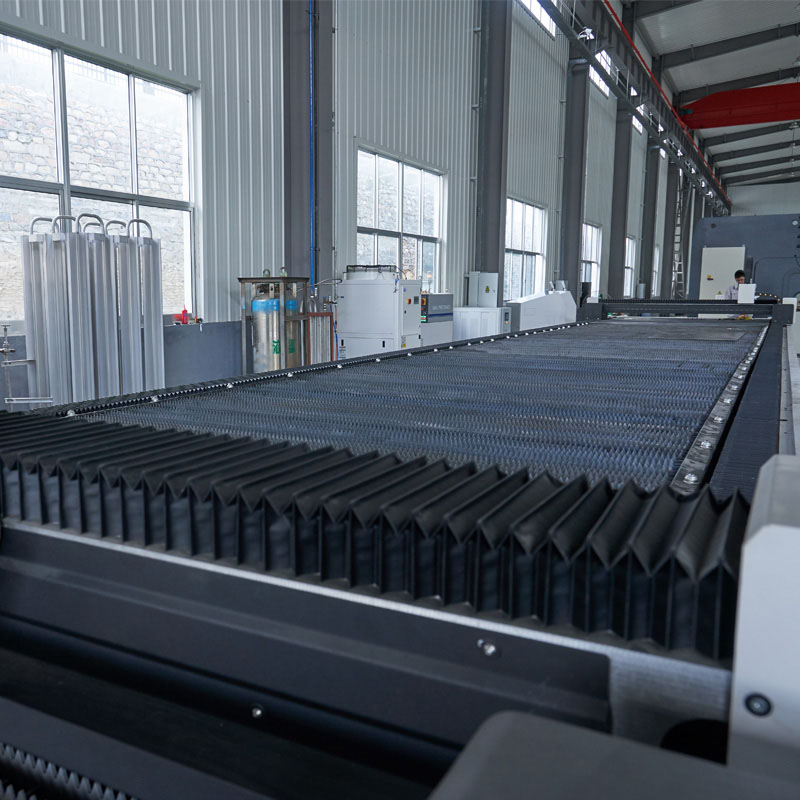

Fiber Laser Cutting Machine

An optical fiber cutting machine is a specialized device that is used to cut materials into the desired shape by focusing fiber bundles into high-energy-density light spots. The fiber cutting machine uses laser technology to transmit the laser beam into the optical fiber and transmits it to the cutting head through the optical fiber. The cutting head focuses the laser beam onto a very small area, producing high enough energy to cut through the material.

Fiber optic cutting machines are widely used in various industries such as metal processing, electronics, automobile manufacturing, and aerospace. It can cut a variety of materials, including metals (such as steel, aluminum, and copper), plastics, wood, textiles, and stone. Fiber optic cutting machines have the advantages of high precision, high speed and flexibility, and can achieve cutting of complex shapes while having a small cutting width and heat-affected zone.

Laser cutting equipment, CNC drilling and cutting in one.

Processing range:

Iron plate: The longest can be processed to 13 meters, the thickest can be processed to T35 and 2.5 meters wide.

Stainless steel plate: up to 13 meters in length and up to T25 in thickness and 2.5 meters in width.

Brass plate: up to 13 meters in length and up to T10 in thickness and 2.5 meters in width.