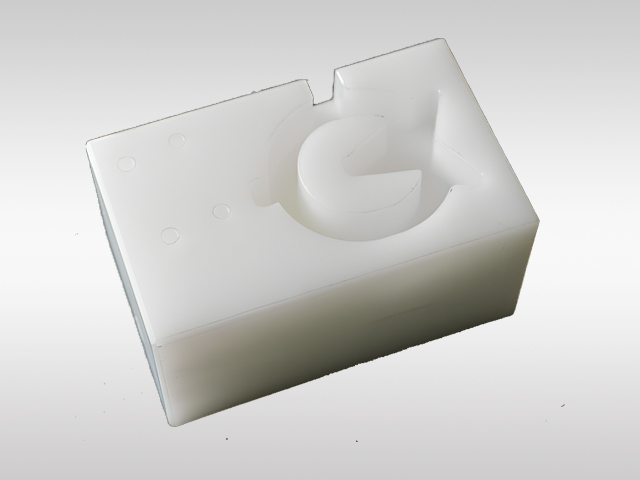

Wire Harness Fixture

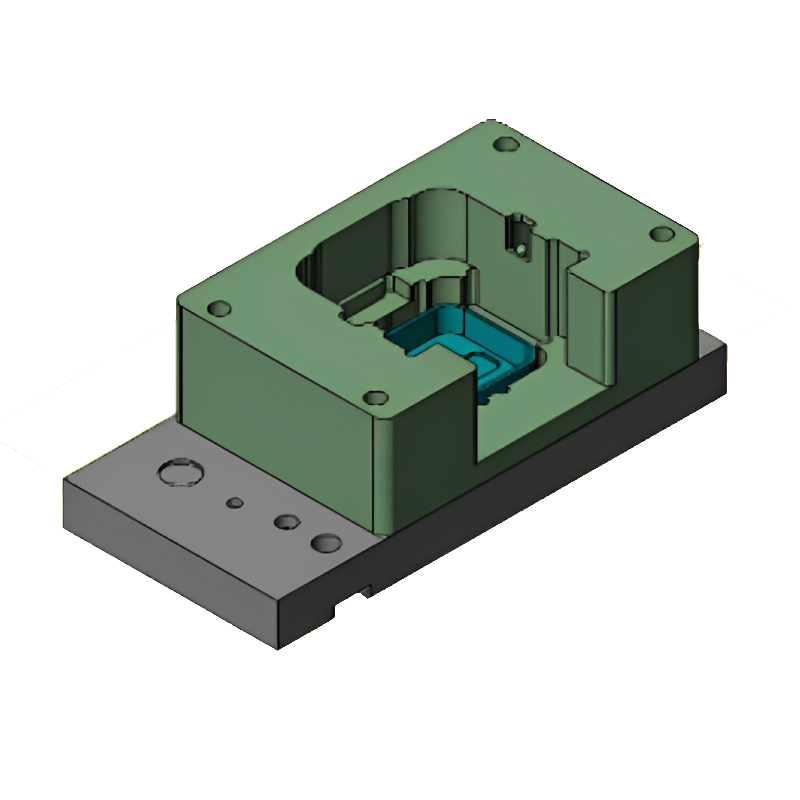

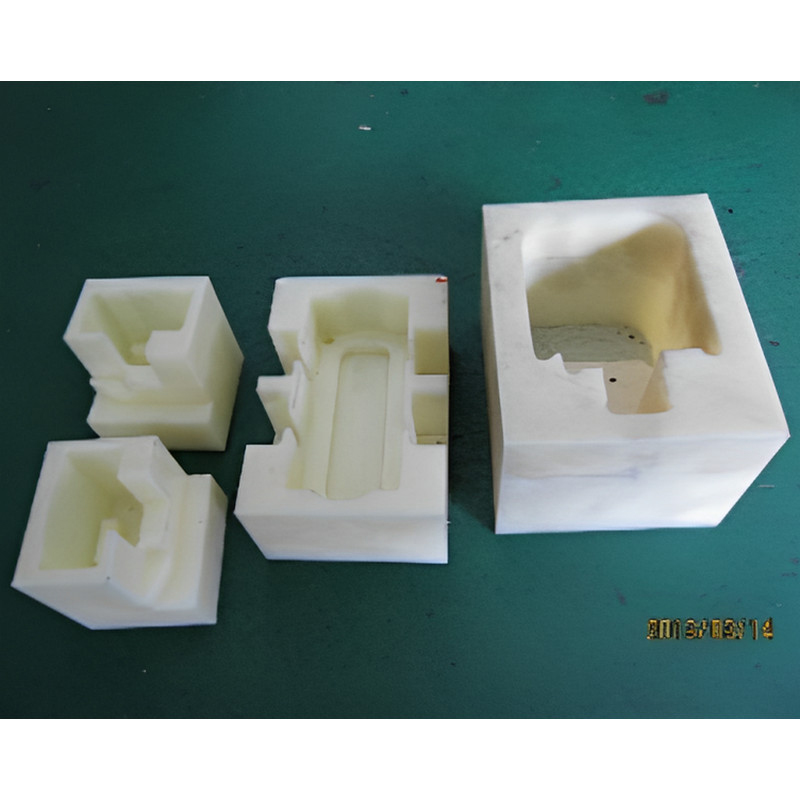

A wire harness fixture is a tool used to fix, position and assemble electrical wiring harnesses. They are typically made of steel or other strong materials and are used to keep wiring harnesses in the correct position and orientation during manufacturing, assembly, and repair.

The harness fixture has the following functions and features:

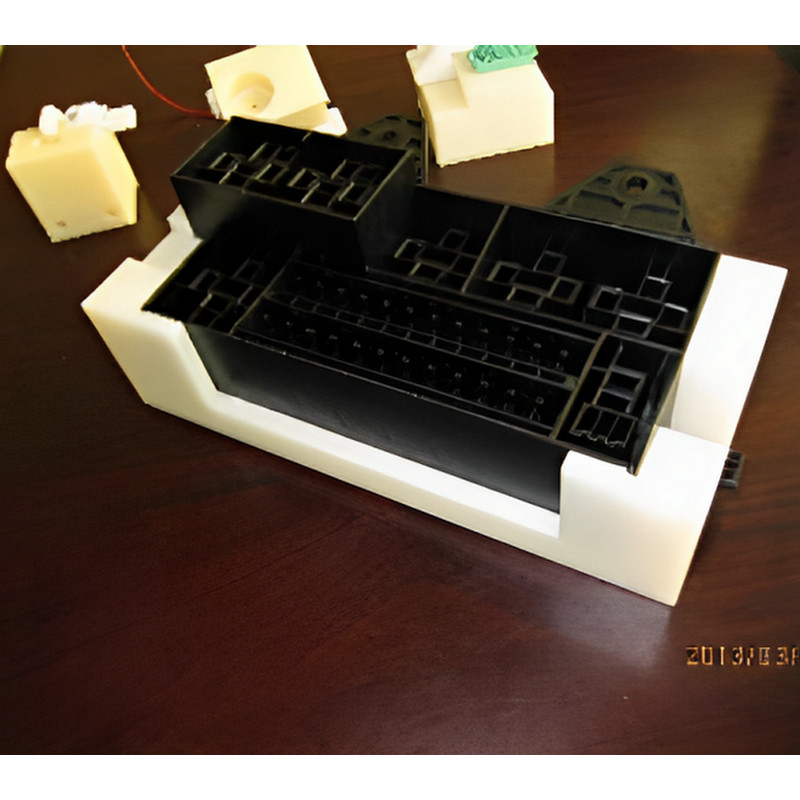

1. Fixing and positioning: The wire harness fixture ensures that it maintains a stable position during assembly by clamping and fixing the wiring harness. This helps prevent the harness from loosening or shifting during vibration, transport or use.

2. Alignment and orientation: The wire harness fixture can ensure the correct alignment and orientation of the wiring harness. They ensure that the connectors of the wiring harness are properly aligned with the corresponding components, avoiding wiring errors or connection problems.

3. Provide working space: The harness fixture can also provide surrounding space, so that the operator can more easily assemble, connect and test on the harness.

4. Fast fixing and releasing: Harness fixtures usually have a fast fixing and releasing mechanism, making them easy to use and operate. This can improve production efficiency and ease of operation.

Wire harness fixtures provide several advantages during harness manufacturing and testing:

1. Improve production efficiency: Wire harness fixtures can automate harness manufacturing and testing process to improve production efficiency. They enable fast and accurate wiring harness connection and testing, reduce the need for manual operations, and increase throughput on the production line.

2. Ensure consistency and quality: Wire harness fixtures can ensure the consistency and quality of harness. By precisely controlling the pin position and test conditions, harness fixtures ensure that each harness meets specification requirements, reducing defect rates and improving product quality and reliability.

3. Improve test accuracy: Wire harness fixtures can provide more accurate test results. By ensuring good contact between the test pin and the harness connector, harness fixtures reduce test errors and interference and improve test accuracy and reliability.

4. Reduce human factors: The wiring harness manufacturing and testing process may be subject to human factors, such as human error or labor fatigue. By using harness fixtures, the influence of human factors on harness quality and test results can be reduced, and the consistency and repeatability of the production line can be improved.

5. Improve safety: Wire harness fixtures can provide a safer working environment. They can reduce risks in manual operation and potential safety issues such as false touch and the risk of electric shock.

6. Reduce costs: Although the input cost of wire harness fixtures may be higher, they can reduce costs in long-term production. By reducing labor requirements, increasing production efficiency, improving product quality and reducing defect rates, harness fixtures can help reduce manufacturing and maintenance costs.

Submitted successfully

We will contact you as soon as possible