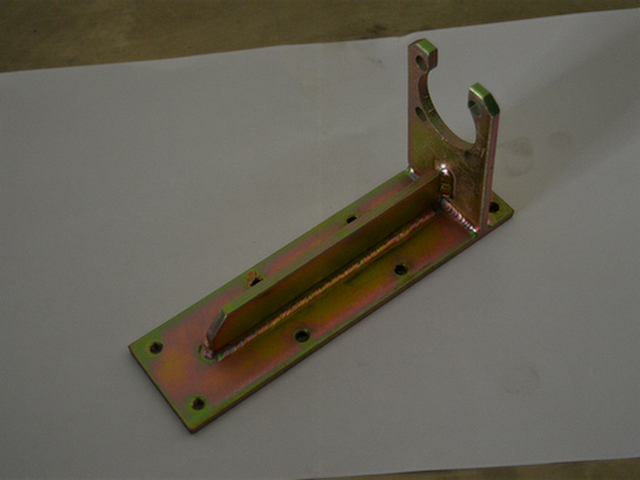

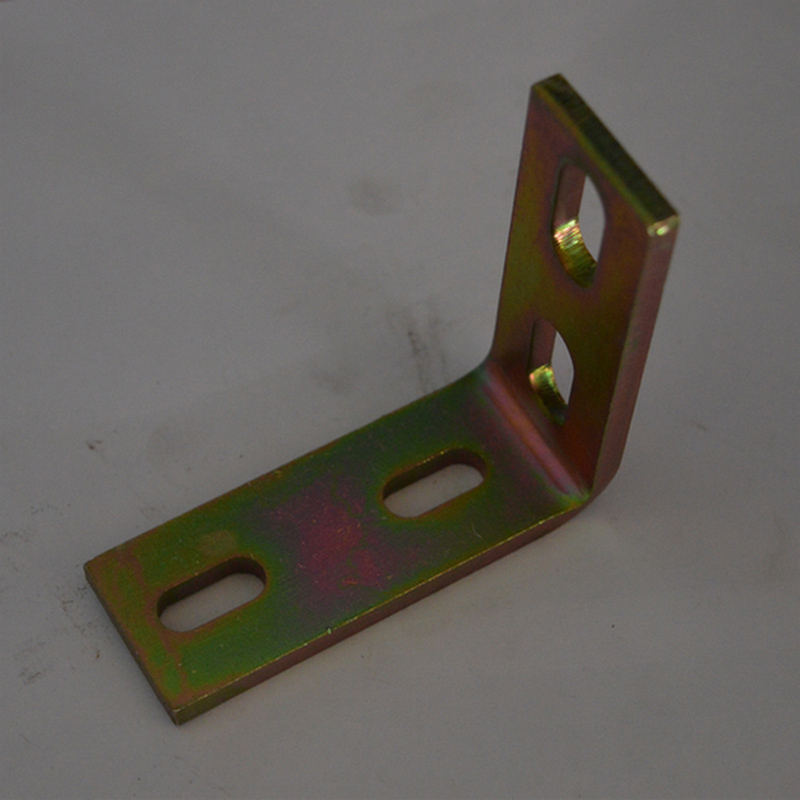

Bending Sheet Metal

Bending sheet metal is an efficient way to manufacture merchandise of unique shapes for exceptional processes. It guarantees simplicity and is an environment friendly way to shape new products, doing so in order to reap the perfect shape or form required through the manufacturing process. Bending is a structure of deformation and one of the three most important procedures in sheet metallic processing; the different two are slicing and joining. Bending sheet metal is performed by way of the use of jigs or dies to keep the workpiece in area and strategically making use of pressure on areas of the workpiece. The utilized pressure should exceed the yield energy of the cloth to motive plastic deformation of the part. This method creates a v-shape, u-shape or groove on the shaft, developing new phase geometry. Bending modifications the shape, however the extent of the workpiece stays the same.

Product advantages:

1. It is handy to deform, so that quite a number types of factors can be manufactured with easy processing technology.

2. Sheet metallic structural components are mild in weight.

3. The quantity of processing is small. Due to the excessive floor fantastic of the bending sheet metal and the small dimensional tolerance in the thickness direction, the plate floor does no longer want to be processed.

4. It is convenient to reduce and weld, and can manufacture giant and complicated components.

5. The structure is standardized, which is handy for automated processing.

Submitted successfully

We will contact you as soon as possible