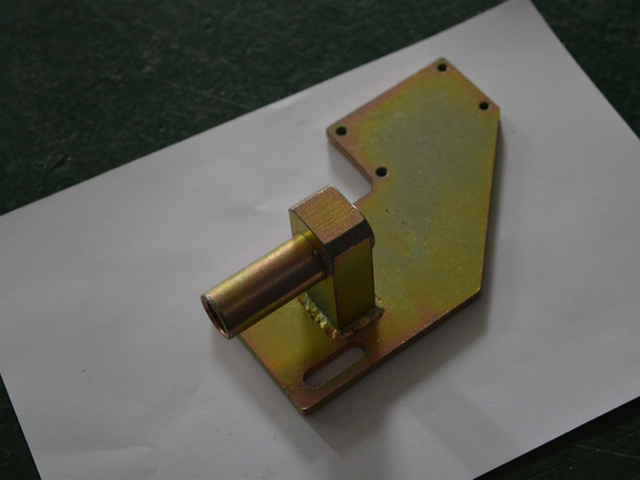

Sheet Metal Bending

The sheet metal bending process of mechanical sheet metal is to install the mold on a device called a plate bending machine, and apply pressure to the cut sheet to bend it linearly at a certain angle. In the plate bending machine, the upper mold (convex mold) is installed on the upper part of the equipment, and the lower mold (concave mold) is installed on the lower part. The upper part of the equipment moves up and down to bend the metal plate, but the angle obtained by bending depends on the batch of materials and the The rolling direction varies, so fine adjustments are required every time, making processing difficult. However, it can be said to be one of the most important processes in sheet metal processing, because the ease and aesthetics of welding processing in subsequent processes will vary greatly depending on the accuracy of the bending process.

Product advantages:

1. Manufacturing speed: Automation and the latest technology enable us to produce large quantities of parts in a relatively short period of time.

2. Accuracy: With proper design taking into account manufacturability, bent sheet metal parts can be very precise.

3. Less post-processing: Unlike welded parts, sheet metal bending require little processing after bending, aside from any additional surface finishing or hardware.

4. Reduced parts count: Since components are made from one piece of material rather than multiple parts with joints, this helps simplify logistics, BOM and reduce overall complexity.

Submitted successfully

We will contact you as soon as possible