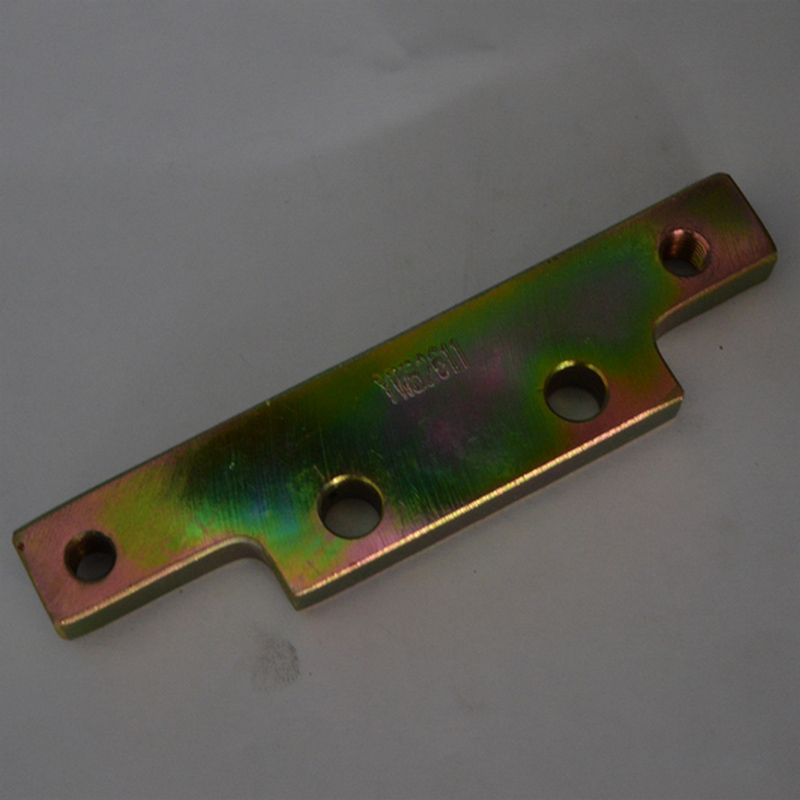

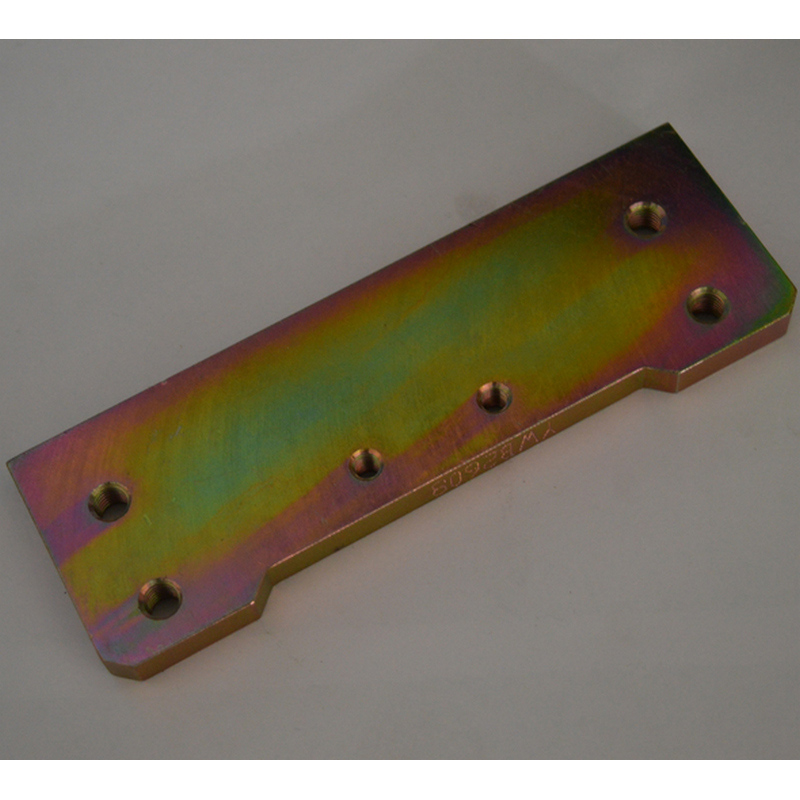

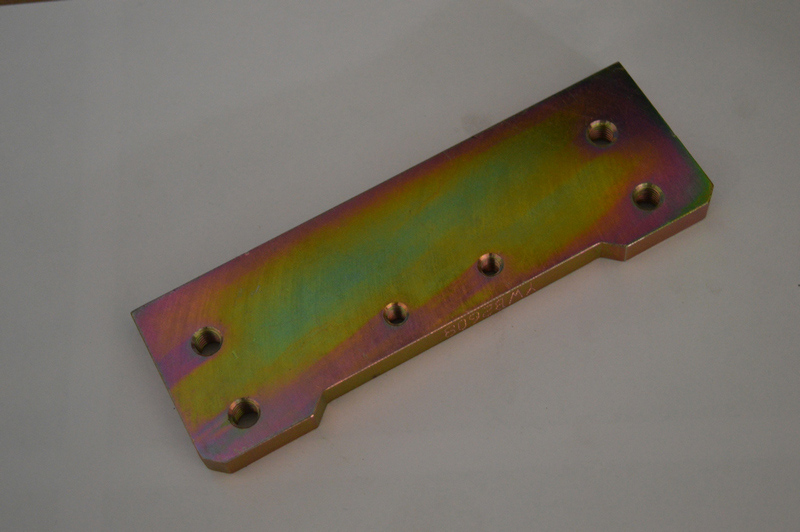

Sheet Stamping

Sheet stamping is called sheet metal processing. Its main material is plate. Through shearing, bending, bending, welding, riveting and other processes, the raw materials are made into products, including items we need in our daily lives. It is unbelievable that a small sheet metal processing product needs to go through so many processes.

Product advantages:

1. Lightweight:Sheet stamping is typically lighter than traditional metal products, making them more practical in many applications. For example, in the automotive manufacturing industry, the use of sheet metal products can reduce the weight of vehicles, thereby improving fuel effciency and performance.

2. Corrosion resistance: Sheet metal products often have a high level of corrosion resistance, which makes them more durable in many applications.

3. Plasticity: Sheet metal products have high plasticity, which allows them to be made into various shapes and sizes. This makes sheet metal products more flexible in many applications and can meet a variety of needs.

4. Ease of processing: Sheet metal products are generally easier to process than other metal products. This makes them more efficient in the manufacturing process and can reduce manufacturing costs.

5. Aesthetics: Sheet metal products usually have a high appearance quality, which makes them more beautiful in many applications. For example, in the furniture manufacturing industry, sheet metal products can be used to create modern and stylish furniture.

6. Recyclability: Sheet stamping can often be recycled, making them environmentally superior. This also makes sheet metal products more popular in many industries because they reduce waste generation.

Submitted successfully

We will contact you as soon as possible