Industry News

News Center

The maintenance of powder processing equipment is very important to ensure the normal operation of the equipment and extend the service life of the equipment. Here are some suggestions for routine maintenance of powder processing equipment:1. Cleaning and lubrication: Regular cleaning of equipment

2023/11/07 08:52

When using powder processing equipment, please pay attention to the following important use considerations:1. Read and follow the equipment operation manual: Before starting to use the powder processing equipment, be sure to read and understand the instructions, safety instructions and maintenance

2023/11/06 09:44

Powder equipment processing line is a powder production line. After the powder equipment is used, it is necessary to do daily maintenance work, which can extend the service life of the product. The following describes the specific maintenance methods:In the use of equipment period, each shift to

2023/11/03 11:03

What are the precautions in the construction of powder spraying equipment? Powder equipment processing line manufacturers to introduce you:The so-called powder electrostatic spraying is the use of high voltage electrostatic corona electric field principle. The high voltage negative electrode is

2023/11/03 10:11

Weighing is one of the most critical processes in powder coating manufacturing. The selection of weighing equipment and the accuracy of weighing process are important factors to determine the accuracy of the formula and the quality of powder coating products.Therefore, it must be based on the

2023/09/25 14:48

Aluminum scrap is not only a kind of waste, it is also a valuable resource that can be recycled. However, the recycling of waste aluminum requires a lot of energy and manpower and material resources, especially when the waste aluminum is piled together, it needs the help of some machines. Scrap

2023/09/25 14:43

The complete powder equipment production line is mainly composed of the following components: raw material processing system, crushing and grinding system, mixing and stirring system, conveying system, drying system, packaging system, etc.The raw material handling system is responsible for the

2023/09/25 14:37

Powder equipment processing lines have excellent processing capacity and production efficiency, and are an integral part of today's industrial production. The production line adopts advanced machine equipment and automation technology, which can greatly improve production efficiency, reduce costs

2023/09/25 14:31

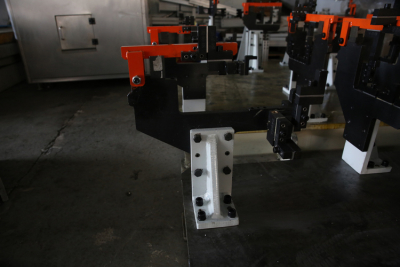

Work fixtures are tools or equipment used to clamp and secure workpieces in industrial production. They are widely used in manufacturing, machining, assembly lines and other processes.Clamps: Including manual clamps and hydraulic clamps, used to fix workpieces and provide stable clamping force.

2023/09/12 16:36

Sheet metal bending is a common processing method and one of the basic processes for making sheet metal components. When bending sheet metal, you need to pay attention to the following aspects.1. Material selection.First of all, it is necessary to select the appropriate material, which must meet

2023/09/11 14:50

1. The heavy work of positioning, clamping and workpiece turning when manually assembling components is changed through mechanical devices, which improves the working stipulations of workers.2. Accurate and dependable positioning and clamping can minimize or even cancel the blanking and marking

2023/09/08 17:55

Since its establishment, the company has been well-known by China Aerospace 513 Institute, Dongyue Powertrain, Delphi Parker Electric, Delphi Automotive Air Conditioning, ZF Automotive Steering System, Yuxin Technology, Yazaki Auto Parts, Haina Brake, Zhenghai Group, etc. Adopted by enterprises,

2023/05/29 16:30