Powder Coating: Environmental Advantages & Challenges

In the pursuit of both efficient production and environmental protection, powder coating technology has emerged as a leading technology in the industrial coating field with its unique environmental advantages. This technology not only significantly reduces pollution to the environment, but also realises the effective use of resources, but also faces some challenges. In this article, we look at the environmental benefits of powder coating and the challenges it faces.

Environmental Advantages

The biggest highlight of powder coating is its excellent environmental performance. Compared with traditional solvent-based coatings, powder coatings do not contain volatile organic compounds (VOCs) and do not produce harmful emissions during the spraying process, thus greatly reducing the pollution of the atmosphere. This is important for improving air quality and reducing greenhouse gas emissions.

In addition, the powder coating process does not require the use of water resources as a diluent, avoiding the problems of wastewater treatment and secondary solid waste disposal, which saves valuable water resources and reduces environmental pressure. This advantage is especially prominent in today's increasingly resource-constrained world.

Powder coating also has a high material utilisation rate. Powder that is not adsorbed by the workpiece can be captured and reused through advanced recycling systems, greatly reducing material waste. This recycling of resources not only reduces production costs, but also meets the requirements of energy saving and emission reduction in modern industry.

Challenges

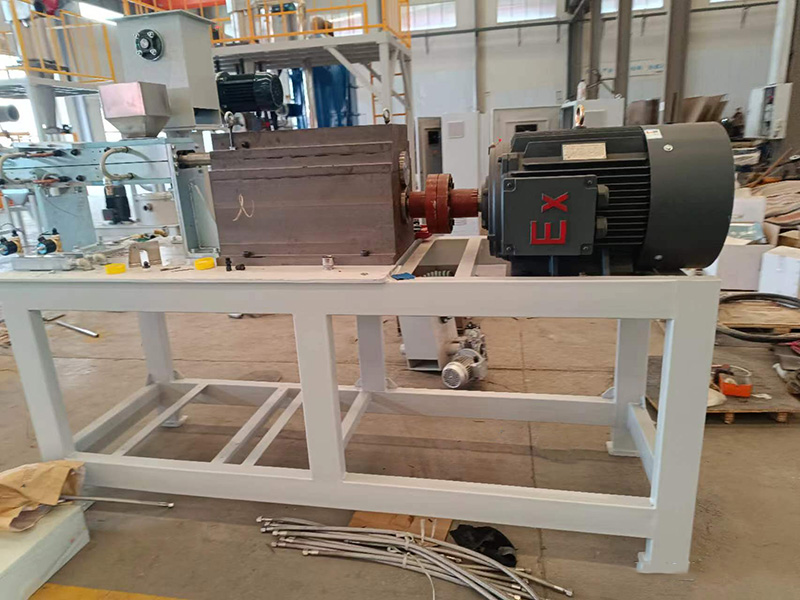

Despite its excellent environmental performance, powder coating still faces a number of challenges in practical application. Firstly, the concentration of dust needs to be strictly controlled during the coating operation to prevent the powder from escaping and affecting the working environment and the health of the staff. This requires companies to equip high-quality powder recovery devices and dust removal systems, and to strengthen on-site management.

Secondly, the initial investment in powder coating equipment is relatively high, including the purchase of equipment, installation and commissioning, as well as personnel training and other costs. This may constitute a certain economic burden for some small enterprises. However, in the long run, the efficient use of powder coating and low-cost maintenance will gradually bridge this gap.

In addition, the relatively limited choice of colours and textures available in powder coating may not be able to meet the individual needs of some specific products. As technology continues to advance, this problem is gradually being solved, but companies still need to give full consideration to product design requirements and market demand when choosing powder coating.

Conclusion

In summary, powder coating plays an increasingly important role in the field of industrial coating with its significant environmental advantages. It not only reduces the pollution to the environment, but also realises the effective use of resources and cost reduction. However, companies still need to face some challenges when applying powder coating technology, including dust control, equipment investment and coating selection. Through continuous technological innovation and management optimisation, it is believed that these challenges will gradually be overcome and powder coating will play a more important role in future industrial development.

Related Products

Submitted successfully

We will contact you as soon as possible