Powder Equipment Troubleshooting: Practicing the "Prevention is Better than Cure" Principle

In the practice of powder equipment troubleshooting, the principle of "prevention is better than cure" is particularly important. The core of this principle lies in the implementation of a series of preventive measures to effectively avoid the occurrence of equipment failures, thereby reducing unplanned downtime, improving productivity, controlling maintenance costs, and ultimately ensuring that the economic benefits of the enterprise grow steadily. The following is an in-depth discussion of the "prevention is better than cure" principle in the field of powder equipment troubleshooting:

First, the core value of preventive measures

1. Reduce downtime: Through the implementation of regular inspection and maintenance strategy, potential failures can be detected in a timely manner and properly dealt with, thus avoiding unplanned equipment downtime due to sudden failures, and ensuring the stability of the production schedule.

2. Improve production efficiency: Preventive maintenance measures can ensure that the powder equipment continues to be in the best operating condition, thereby improving production efficiency and product quality and creating more value for the enterprise.

3. Reduce maintenance costs: preventive maintenance can reduce the high repair costs due to equipment failure, and effectively extend the service life of the equipment, reducing long-term operating costs.

4. Ensure safe production: powder equipment in the operation process may face high temperature, high pressure and other safety risks, the implementation of preventive measures to help reduce the probability of safety accidents, to protect the safety of personnel and equipment.

Second, the specific prevention strategy

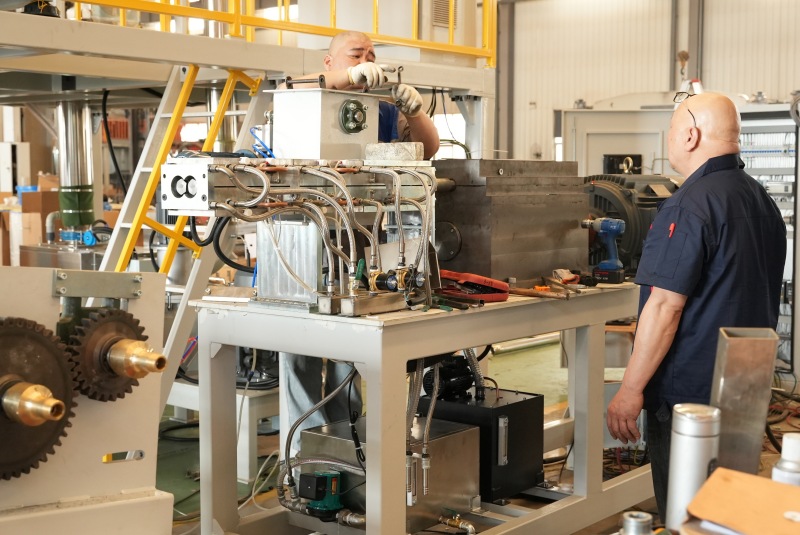

1. Regular inspection and maintenance: Develop a detailed equipment inspection and maintenance program, and conduct a comprehensive inspection of powder equipment on a regular basis, covering mechanical components, electrical systems, lubrication systems and other aspects. For the problems found, it is necessary to deal with them in time to prevent further deterioration of the problem.

2. Strengthen operation training: provide professional training for equipment operators, so that they have an in-depth understanding of the working principle of the equipment, operating specifications and daily maintenance knowledge, to improve the skill level of the operators, and reduce the equipment failure caused by improper operation.

3. Optimize the operating environment: Ensure that the operating environment of the powder equipment meets the requirements of the equipment, including appropriate temperature, humidity and ventilation conditions. For equipment with special requirements, additional protective measures need to be taken.

4. Adopt advanced monitoring technology: Use sensors, data acquisition systems and other advanced technologies to monitor and analyze the operating status of the powder equipment in real time, in order to find out the abnormalities in time and issue an early warning.

5. Establish an emergency mechanism: develop an emergency plan for equipment failure, clarify the troubleshooting process and the responsible person, to ensure that when the equipment fails to respond quickly and take effective measures to deal with it.

Third, the implementation of preventive strategies recommended

1. Enhance the awareness of prevention: the importance of preventive maintenance of equipment should be highly valued to enhance the preventive awareness of all personnel.

2. Improve the management system: establish and improve the equipment preventive maintenance management system and operating procedures, clarify the specific requirements of the work and the responsible person, through the system constraints to ensure that the preventive measures are effectively implemented.

3. Strengthen technical support: actively introduce and apply advanced monitoring technology and maintenance tools to enhance the scientific and technological content and efficiency of preventive maintenance work. At the same time, strengthen the cooperation and exchange with professional organizations, and constantly improve their own technical level and management ability.

To summarize, the principle of "prevention is better than cure" plays an important role in the diagnosis of powder equipment failure. Through the implementation of a series of effective preventive measures, it can significantly reduce the equipment failure rate, improve the production efficiency, and provide a strong guarantee for the economic benefits of enterprises and safe production.