What are the advantages of powder coating mixers?

As a kind of equipment widely used in various industries, the powder coating mixer has many advantages, which makes it occupy an important position in the field of material mixing. The following will elaborate on the advantages of the mixer.

First of all, the mixer has excellent mixing effect. It uses advanced mixing technology, such as counter-current mixing principle, so that all kinds of materials in a short time to achieve uniform mixing. The various parts of the mixer are reasonably designed and configured to ensure the uniformity and efficiency of mixing. Whether in powder or granular form, mixers can effectively mix materials to meet the needs of a wide range of industries and products.

Secondly, the operation of the mixer is simple and does not require too many technical requirements. The operator only needs to follow the instructions and operation steps to complete the mixed task. This ease of operation makes the mixer the preferred equipment for many enterprises, reducing the skill requirements for operators and improving production efficiency.

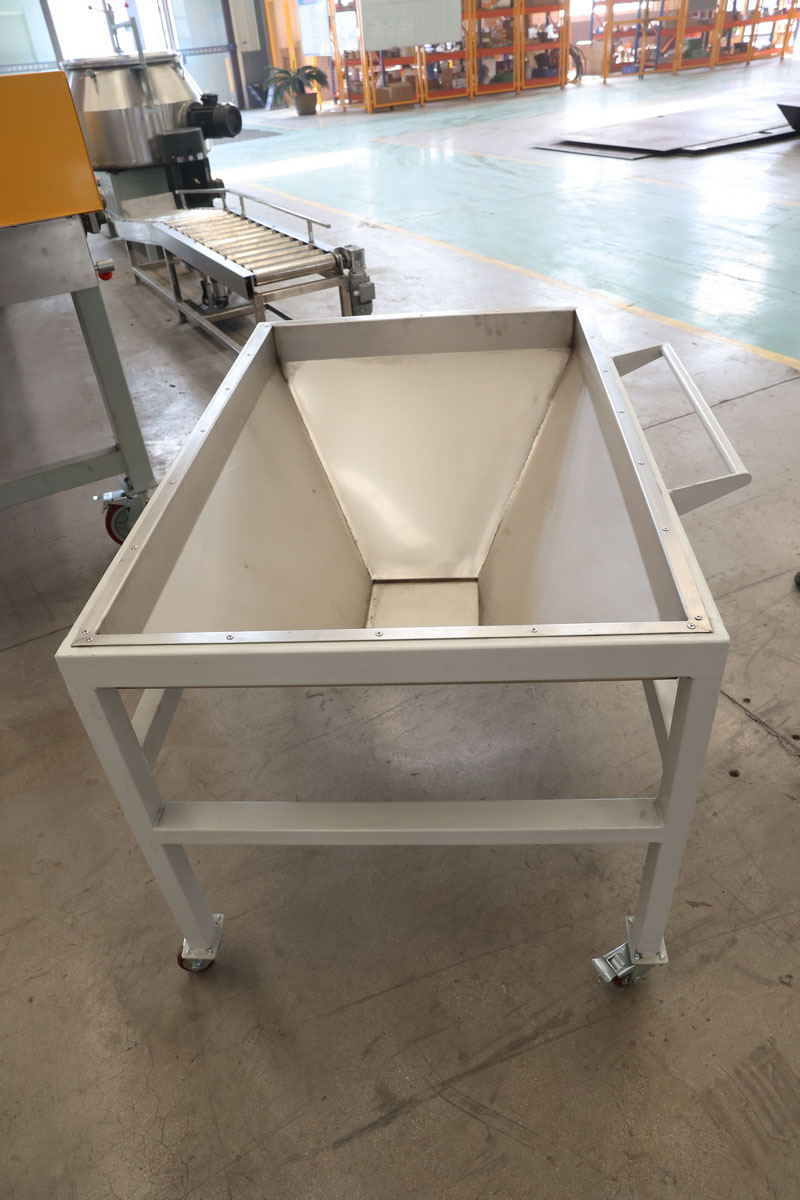

Moreover, the mixer has a wide range of applications. It can not only be used for mixing powdered materials, but also for processing materials in different states such as granular. This makes the mixer widely used in chemical, food, medicine and other industries. At the same time, the mixer also has the characteristics of small size and compact structure, which can adapt to the site conditions of different factories and has strong adaptability.

In addition, the mixer also performs well in terms of environmental protection. It consumes less energy in the mixing process, does not produce excessive noise and pollution, and meets the environmental protection requirements of modern chemical production. This provides strong support for enterprises to achieve green production.

Powder coating mixers also have the advantage of customised services. According to the customer's needs and process requirements, the mixer can provide customers with the best mixing solution. Whether it is the configuration, performance or appearance of the equipment, it can be customized according to customer needs to meet the special needs of different industries.

In terms of after-sales service, the mixer also performs well. Suppliers will provide customers with perfect after-sales service, including equipment installation, commissioning, maintenance and training services, to ensure that customers can use and maintain equipment smoothly. This comprehensive service provides customers with a strong guarantee and reduces the risk of use.

In summary, the powder coating mixer has become a leader in the field of material mixing by virtue of its excellent mixing effect, simple and easy operation, wide range of application, energy saving and environmental protection, customized service and perfect after-sales service. Whether in terms of production efficiency, product quality or environmental protection, the mixer has shown strong competitiveness and created greater value for enterprises.