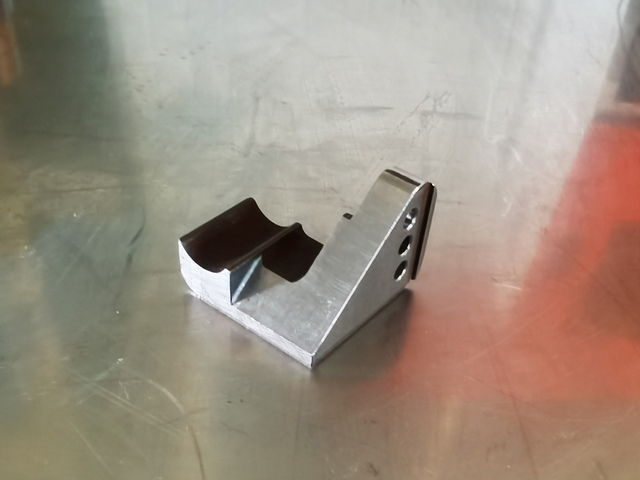

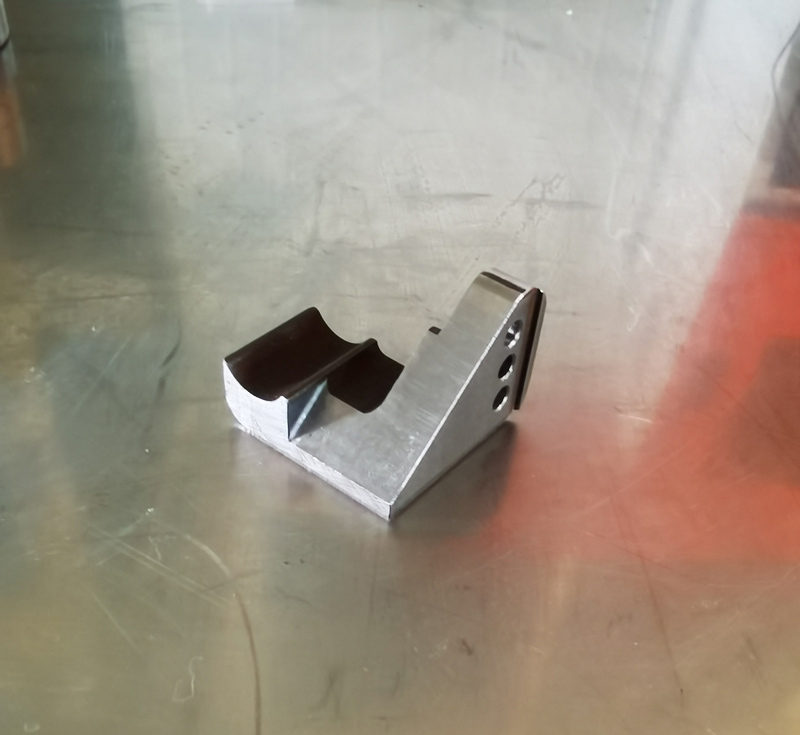

Sheet Metal Parts

Sheet metal parts are important parts made of cold working metal sheets. In the field of manufacturing and engineering, sheet metal parts are widely used in the manufacture of various metal structures and parts.

The process of making sheet metal parts involves a variety of processes, such as cutting, punching, bending and welding. First, the sheet metal is cut according to specific design requirements to obtain the desired size and shape. Then, through the punching process, holes and notches are processed in the metal plate. Next, using a bending process, the sheet metal is bent to the desired Angle and shape. Finally, by welding or other joining methods, the required parts are partially assembled together to form the final product.

Sheet metal parts have many advantages that make them widely used in the manufacturing and engineering fields. Here are some of the main advantages of sheet metal parts:

1. Lightweight: Compared to traditional cast or forged parts, sheet metal parts are made of sheet metal, so the weight is relatively light. This gives sheet metal parts a distinct advantage in applications that require light weight, improved fuel efficiency or load capacity.

2. High strength: sheet metal parts after cold processing, can enhance its strength and rigidity. Through proper design and process control, sheet metal parts can be made with enough strength to withstand various stresses and loads.

3. Manufacturing flexibility: sheet metal parts can form complex shapes through stamping, bending, stretching and other processes to meet various needs. This manufacturing flexibility allows sheet metal parts to meet the design requirements of different products, providing more choices and possibilities during the engineering design process.

4. High precision and consistency: The manufacturing process of sheet metal parts can be achieved with high precision and consistency through automated equipment and process control. This means that sheet metal parts can meet strict dimensional requirements and quality standards, ensuring the interchangeability and quality stability of parts.

5. Cost effectiveness: Because the production process of sheet metal parts can be mass produced and automated production, the production cost is relatively low compared to other manufacturing methods. In addition, sheet metal parts can also reduce material costs by optimizing design and material utilization.

6. Diversified surface treatment: sheet metal parts can be sprayed, electroplating, polishing and other surface treatment methods to increase beauty and corrosion resistance. This allows sheet metal parts to meet the appearance and functional requirements of different industries and applications.

Submitted successfully

We will contact you as soon as possible