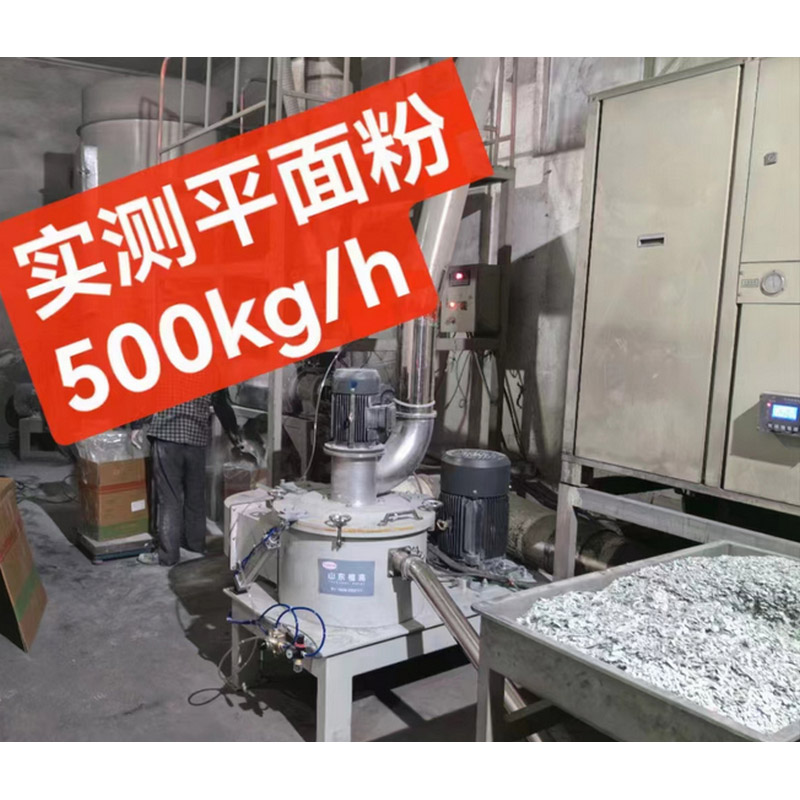

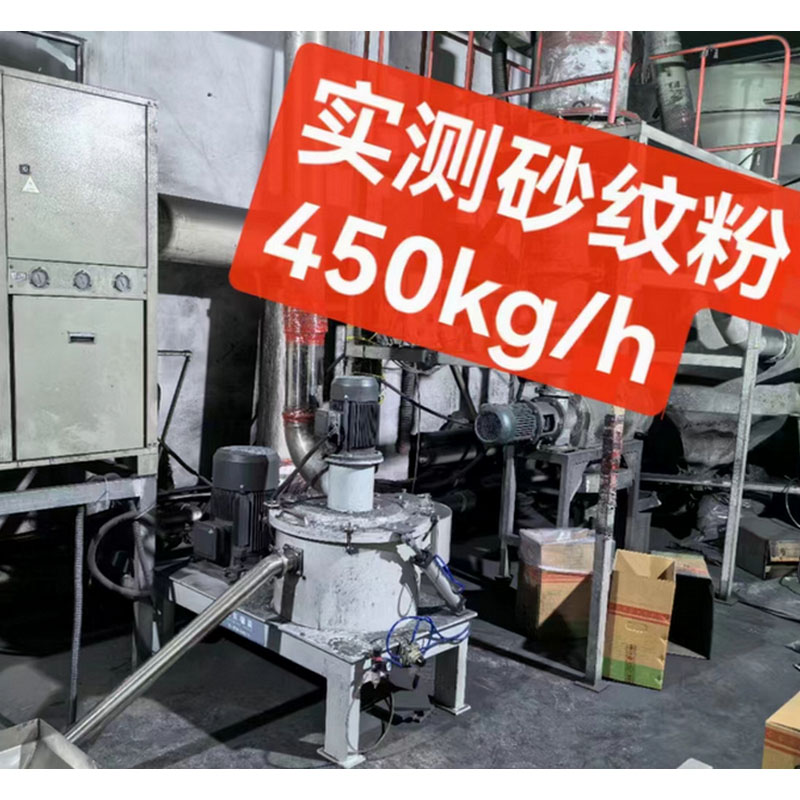

500KG Powder Grinding Machine

The 500KG powder grinding machine has the following significant working advantages:

1. High efficiency and energy saving: The use of advanced grinding technology can complete the grinding work of a large number of materials in a short time to improve production efficiency. At the same time, the energy saving factor is fully considered in the design and manufacturing process of the machine, which reduces energy consumption and saves costs for enterprises.

2. Easy operation: The machine adopts automatic control system, easy operation, only need to set the parameters, you can realize automatic operation. In addition, the maintenance is also very convenient, reducing the labor intensity of workers.

3. Wide range of application: 500KG powder grinding machine is suitable for grinding a variety of materials, such as food raw materials, chemical raw materials, pharmaceutical raw materials, etc., with strong versatility.

4. Safe and reliable: The machine is fully considered in the design of safety factors, the use of multiple safety protection measures to ensure the safety of operators. At the same time, the choice of wear-resistant materials and strict manufacturing process ensure the long-term stable operation of the machine.

The working principle of the 500KG powder grinding machine is carefully designed and manufactured, and its core mechanism mainly relies on the friction and impact of the material between the high-speed rotating mill disc and the fixed grinding ring. When the motor starts and the driving spindle begins to rotate, the material on the mill disk is quickly thrown to the grinding ring due to the role of centrifugal force. In this process, the material is not only affected by the centrifugal force, but also by the shear force, friction force and impact force generated by the relative motion between the disk and the grinding ring.

The combined action of these forces produces a powerful grinding and crushing effect on the material. Specifically, the material is subjected to constant friction and impact in the narrow gap between the grinding disc and the grinding ring, causing its structure to gradually disintegrate and eventually transform into the desired powder form. By adjusting the size of the gap between the grinding disc and the grinding ring, the fineness of grinding and grinding can be controlled to meet different production needs. At the same time, by adjusting the speed of the spindle, the movement speed and collision frequency of the material between the grinding disc and the grinding ring can be affected, so as to achieve accurate control of the output and fineness.

This working principle makes the 500KG powder grinding machine has the characteristics of high efficiency, stability and control, and can meet the diverse needs of different industries for material grinding and crushing. Whether it is in the field of food, chemical or pharmaceutical, the machine can play its excellent performance and provide strong support for the production activities of enterprises

Submitted successfully

We will contact you as soon as possible