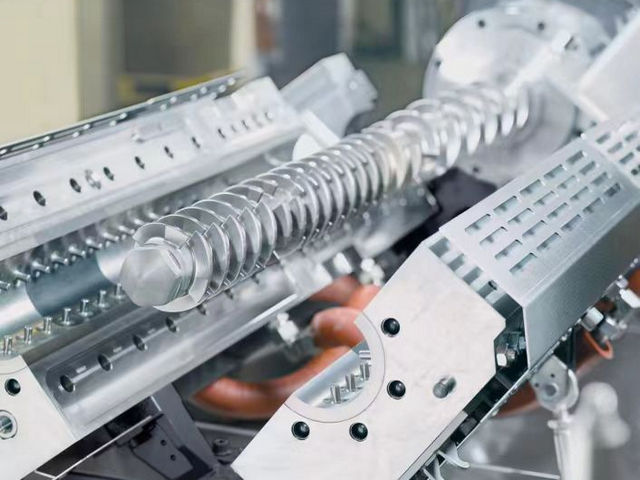

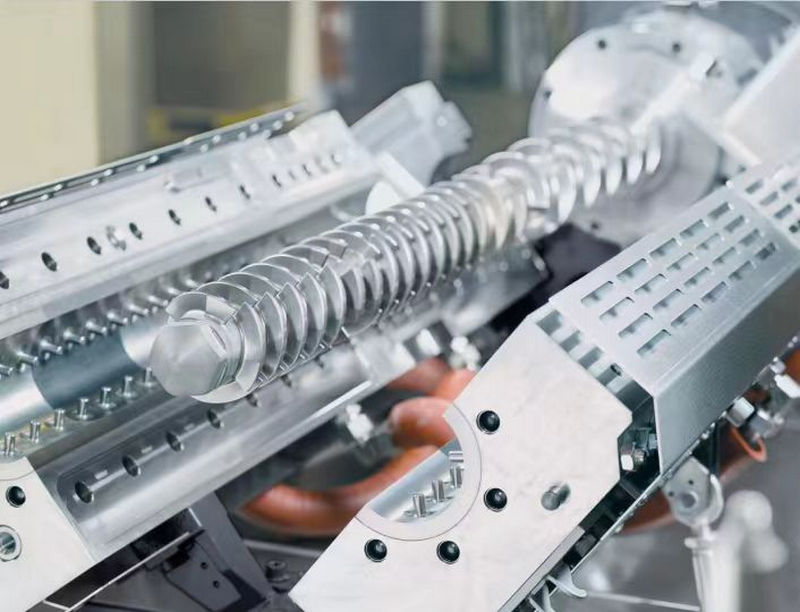

Single Screw Reciprocating Extruder

Single screw reciprocating extruder is a kind of equipment used for plastic processing and extrusion molding. It uses a single screw to complete the process of plastic melting, extrusion and molding. Different from the continuous extruder, the screw of the single screw reciprocating extruder is reciprocating, that is, the screw moves forward after the extrusion plastic, and then returns back, and the extrusion operation is repeated.

Single-screw reciprocating extruders usually consist of four main parts: feed system, screw system, heating and cooling system, and extruder head. The feed system is used to feed plastic particles or powders to the extruder screw, which is responsible for heating, melting, stirring and extruding the plastic. The heating and cooling system is used to control the temperature of the screw and barrel to ensure that the plastic can be melted and cooled to the proper state. The extruder is responsible for forming the desired shape of the plastic product and cutting or molding it.

Single screw reciprocating extruder has the following advantages:

1. Efficient production: single screw reciprocating extruder adopts reciprocating motion design, through the reciprocating extrusion action, can achieve high-speed and efficient production of plastic products. Compared to traditional single-screw extruders, reciprocating extruders can produce more product in the same amount of time.

2. Energy saving: The design of the single-screw reciprocating extruder makes the use of energy more efficient. Through the working principle of reciprocating motion, the running time and energy consumption of the motor can be reduced, and the overall energy consumption can be reduced.

3. Uniform melting material: reciprocating motion can help achieve uniform and stable melting material. The reciprocating motion inside the extruder can form shear force and mixing effect in the melt material, making the melt material more evenly organized and melted, improving the quality and consistency of the product.

4. Wide range of application: single screw reciprocating extruder is suitable for processing a variety of plastic materials.

5. Simple operation: Compared with some complex extrusion equipment, the design of single-screw reciprocating extruder is relatively simple and relatively easy to operate. This allows operators to get started quickly, reducing operational difficulty and training costs.

Submitted successfully

We will contact you as soon as possible