Cooling Belt YPJ1400

The work of pressing, chilling, and crushing materials is finished during the powder-making process. The pressing roller compresses and cools the hot extruder material before it is transported by a steel belt and air-cooled. It is crushed into the minute flake materials needed by the air classifying mill once it reaches the crushing roller.

Depending on the demands of the user, the tablet's thickness can be freely changed between 0.5 and 3mm. The surfaces of the crushing and tablet rollers are hard chrome coated. The YPJ1400-6 cooling belt is distinguished by outstanding performance, a broad application scope, ease of use, and great operational reliability.

Product Details:

Cooling belt machine is pushed through a frequency conversion motor, and the sprocket is pushed by using a reducer. The discount gadget drives the nodal stainless metal conveyor belt, the tablet roller, and the crushing roller to pass synchronously.

The material extruded by way of the extruder falls vertically between the two rollers, and as the curler rotates, the material is delivered into the hole between the rollers for extrusion. Because cold water flows via the tableting roller, its floor has a decrease temperature, inflicting the floor to decrease sharply and spoil away from the fabric after it arrives, and the tableting technique is accomplished continuously. The thickness of the tablet can be adjusted by using adjusting the hole between the tablet rollers.

Product Parameters:

Cooling strip length | 5000mm |

Cooling strip width | 1200mm |

Total power | 3Kw |

Maximum productivity | 650kg/h |

Customer Case:

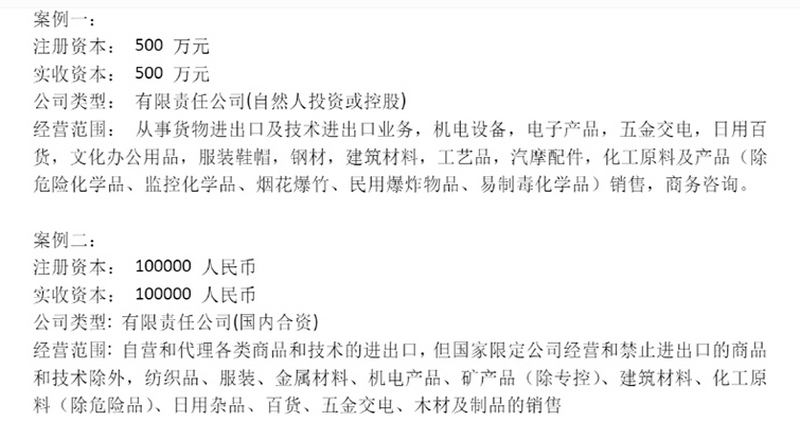

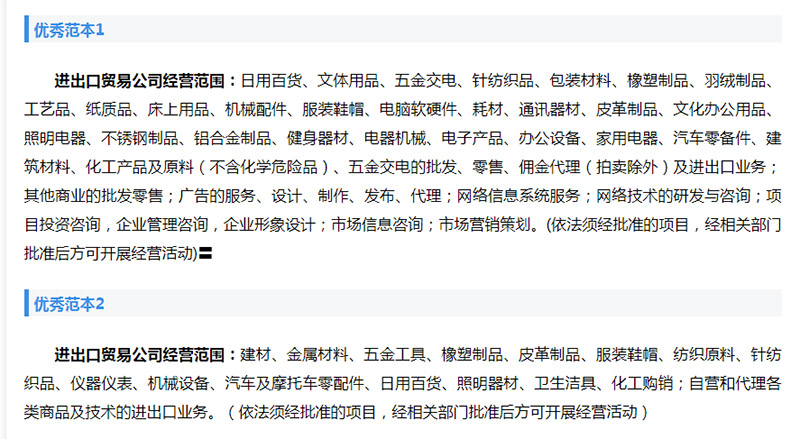

Import and export of goods, import and export of agents, import and export of technologies, and import and export of various kinds of commodities and technologies as prescribed by law. For example, chemical raw materials, hardware and electricity, building materials, office supplies, electronic products and so on.

Submitted successfully

We will contact you as soon as possible