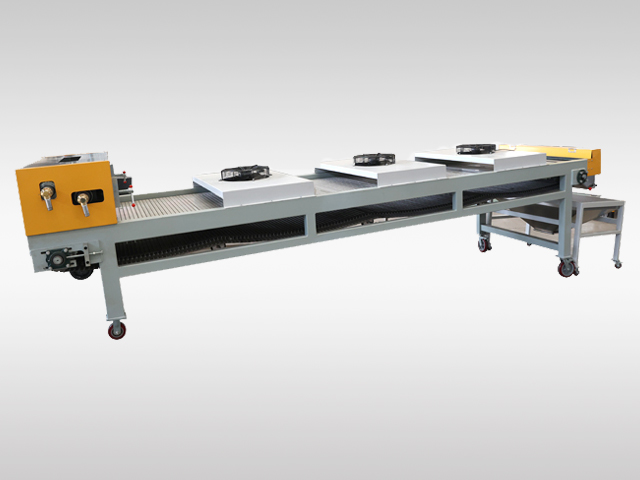

Cooling Belt YPJ800

Cooling belt YPJ800 done cooling and crushing substances in the manner of powder making.

The warm fabric of the cooling belt is compressed and cooled by way of the urgent roller, and then conveyed by way of the conveying metal belt and cooled through air. After accomplishing the crushing roller, it is overwhelmed into small flake substances required through the air classifying mill.

The thickness of the pill can be adjusted arbitrarily inside the vary of 0.5-3mm in accordance to the wishes of users. Tablet curler and crushing curler are plated with tough chrome on the surface. YP800-6 pill press has the traits of terrific performance, extensive software range, easy operation and excessive working reliability.

Product Details

Cooling belt YPJ800 is driven through a frequency conversion motor, and the sprocket is pushed via a reducer. the discount gadget drives the nodal stainless steel conveyor belt, the pill roller, and the crushing curler to move synchronously.

The material extruded by the extruder falls vertically among the two rollers, and as the curler rotates, the new material is brought into the gap among the rollers for extrusion. Because cold water flows through the tableting roller, its surface has a lower temperature, so that the floor of the material shrinks sharply after attaining it and separates from it, and the tableting process is completed continuously. The thickness of the tablet may be adjusted with the aid of adjusting the space between the tablet rollers.

Product Parameters:

cooling strip length | 5000mm |

cooling strip width | 1200mm |

total power | 3kw |

maximum productivity | 650kg/h |

Submitted successfully

We will contact you as soon as possible