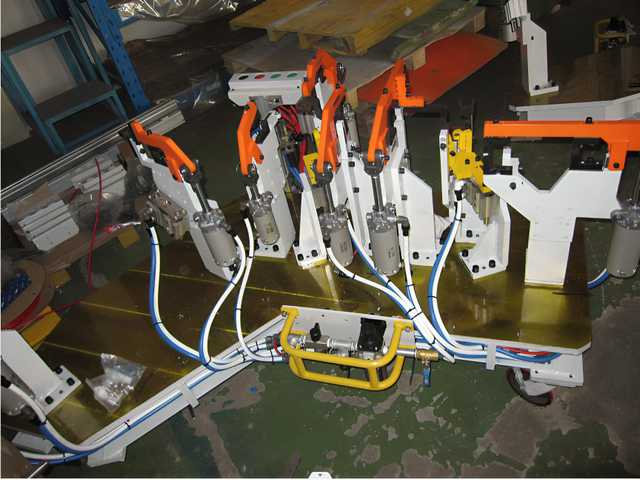

Auto Body-In-White Welding Fixture

The use of welding fixtures in welding processes is the main production process in the automobile manufacturing industry. The application of auto body-in-white welding fixture is directly related to the efficiency, precision and quality of welding processes. In many automobile manufacturers in China, welding fixtures usually use special fixtures, which are equipped for one or several specific welding processes. With the current development trend of small batches and personalization of automobile production, this kind of tooling is widely used, and its design and production cycle is short, which improves the welding process level of my country's automobile manufacturing industry and shortens the development cycle of new models. In the automobile manufacturing industry in the world's advanced countries, the widely used welding fixtures have been standardized and serialized, and only reasonable selection can be made during design. Welding clips have fully experienced its use value, the use examples in automobile production, in actual work, multiple working platforms or various modules can be used to connect and combine, extending the working area to suit various working conditions, and more The production and use of various vehicle models.

Welding, general assembly and painting in the welding fixture of steam side are the core work of car body manufacturing. In welding, welding fixture is the main factor to ensure the welding quality of the car body and an important part of the welding process. It can ensure the shape, The size and precision meet the technical requirements of the product drawing. It can be said that the welding fixture is the "core" circle that constitutes the body welding production line. It is an important factor to ensure the quality of the body welding and affects the manufacturing accuracy and production cycle of the entire car. Therefore, the design of auto body-in-white welding fixture in the automobile manufacturing process is particularly important.

1. Composition of auto body-in-white welding fixture.

Welding fixture is an auxiliary means in the production of products. It is a general term for the process equipment used for assembly and welding, including the guiding device for guiding the welding torch or the workpiece, which quickly and accurately locates and fixes the workpiece at the desired position. Welding fixture is an indispensable auxiliary device for metal structure welding and an important part of the welding process. It mainly maintains and ensures that the shape and size of the welded product meet the requirements of the product drawing during the welding process, facilitates the welder's operation, and improves work efficiency. role. Paper Format, Body. The components of the welding fixture mainly include self-made parts, standard parts and purchased parts. Self-made parts mainly include support blocks, clamping blocks, pattern plates, etc.; standard parts mainly include pins, angle seats, reference blocks, adjusting gaskets, etc.; purchased parts mainly include cylinders and various shaft sleeves, the most core, The most common structural parts include support blocks, clamping blocks, templates, corner seats, adjusting gaskets, etc. Therefore, before designing the welding fixture, it is necessary to fully understand the welding process of the car body and the structural characteristics of the welding fixture, and reasonably carry out solid modeling, call of standard parts and selection of purchased parts.

2. Design requirements for auto body-in-white welding fixture.

2.1 Basic requirements for body welding fixtures.

(1) For body parts and assemblies that should be interchangeable after stamping parts are assembled and welded, the matching parts of the body should be used, especially the shape and size of the holes meet the technical requirements.

(2) The assembly, positioning and clamping can be performed quickly and accurately. The parts to be welded should be easy to operate. After the clamping mechanism is released, the weldment can be easily removed from the fixture, and it is safe and reliable.

(3) When designing the fixture, it is necessary to pay attention to the conduction and insulation problems of some parts on the fixture, so as to improve the quality of assembly and welding of the body.

(4) Due to the complex structure of the body, the design of positioning parts and clamping parts should fully consider the processing technology and the generalization and standardization of parts, so as to facilitate the replacement of wearing parts and restore the original design accuracy.

(5) The assembly and welding jig of the body assembly is relatively complicated and heavy, and it is often necessary to adjust the sample holder for adjustment and correction during manufacturing and use.

2.2 Selection of welding positioning datum.

When clamping the workpiece, the reference used to make the workpiece occupy the correct position in the fixture is called the positioning reference. The correct selection of the positioning reference will directly affect the assembly accuracy of the workpiece.

2.3 Positioning method and positioning components.

The main object of the body welding fixture is the stamping part. Due to the complex shape and easy deformation, the curved surface shape, the shaped platform on the curved surface, the steps formed by drawing and bending of the workpiece, and the Positioning of trimmed windows and outer edges, assembly holes and process holes.

Due to the complex shape of the stamping parts, they directly contact the positioning components during the clamping process, which determines the special shape of the positioning components. The commonly used positioning components are as follows:

(1) Locating pins: Locating with locating pins is a commonly used positioning method in auto body-in-white welding fixture. The reinforcement beam of the cab bottom plate is thickened and has good rigidity, which can be regarded as a rigid assembly. The suspension holes in the base plate can be positioned with two cylindrical pins.

(2) Positioning block: The door opening of the cab and the front and rear windshields are all positioned by the positioning block on the positioning body. The positioning block and the body are designed separately, avoiding the overall profiling process, and making the manufacturing and adjustment of the positioning components much simpler and more convenient.

(3) Semicircular block: Cylindrical workpieces are generally positioned with V-shaped blocks, but when the positioning elements in the welding fixture need to be conductive at the same time, or when the thickness of the workpiece tube wall is less than 0.5D (D is the diameter of the workpiece), In order to prevent workpiece clamping and deformation, semicircular blocks are often used for positioning. The minimum diameter of the hole of the semicircular block shall be the maximum diameter of the workpiece positioning reference axis.

(4) Curved positioning plate.

2.4 Work clamping device.

When the body is assembled and welded, the workpiece must be clamped with the help of a clamping machine to overcome the elastic deformation of the workpiece and the influence of other external forces, so as to ensure that the positioning reference plane of the stamping part of the body is closely attached to the non-positioning block. During welding, the device that applies external force to the workpiece to keep it in a predetermined position is called a clamp. There are many types of clamps. According to the principle of action, there are levers, wedges, screw pairs, eccentric wheels, etc.; according to the source of external force, there are manual, pneumatic, hydraulic, etc. The design of these clamping mechanisms is similar to that of general machine tool fixtures. The designs are similar with minor differences, which can be used for reference.

2.5 Body assembly welding fixture.

Body assembly welding jigs are divided into one-time positioning and multiple positioning according to their positioning methods. The general assembly fixture for one-time assembly and positioning means that the main assembly and welding work of the body assembly is completed on one general assembly fixture. The parts, assemblies, and sub-assemblies that make up the body are sequentially installed on the assembly fixture, positioned and clamped, and are not removed from the fixture until the main assembly and welding work of the body assembly is completed. The feature of this fixture is that the positioning and clamping are only performed once when the body is assembled and welded, which is easy to ensure the quality of the assembled and welded body. According to the body production program, one or several same fixtures can be set up. A single fixture can use a fixed bottom plate, and multiple fixtures can be arranged on the body assembly and welding production line and move with the production line. This kind of fixture that moves with the production line is called accompanying. fixture. The manufacturing of the accompanying fixture is complicated and the cost is high. For the electricity and water and air circuits on each welding station, quick sockets or connectors are designed.

Submitted successfully

We will contact you as soon as possible