Automotive Assembly Fixtures

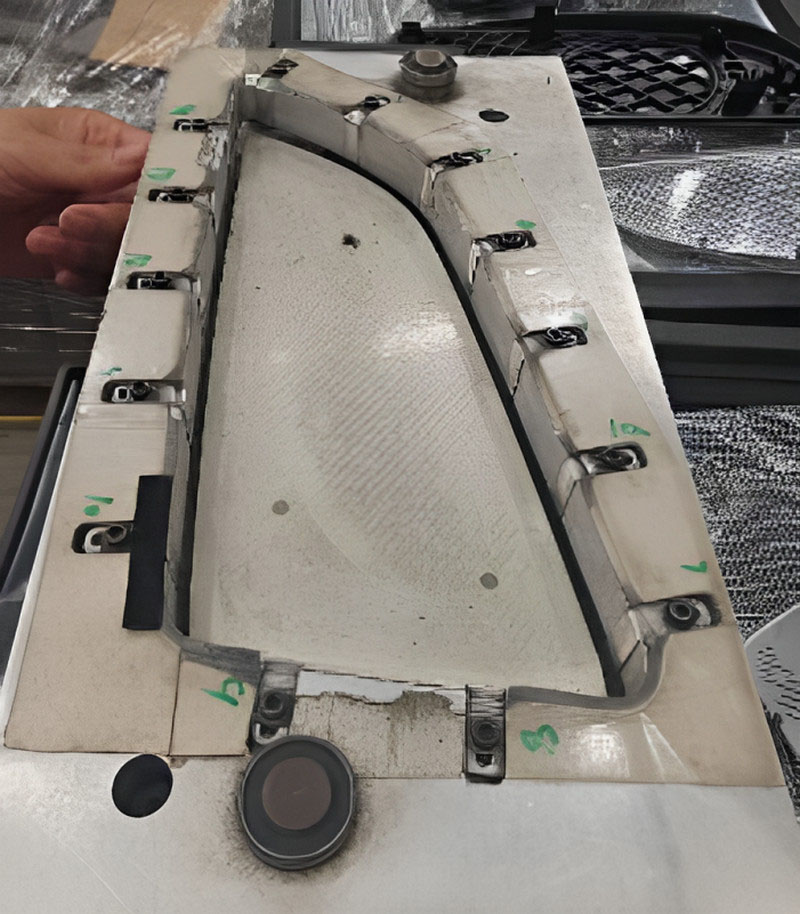

A automotive assembly fixtures is a precise device or piece of tools used in the manufacturing and manufacturing process. They are usually used to fix, function and assist workpieces to make certain their correct role and balance at some point of processing, assembly, calibration, measurement, etc.

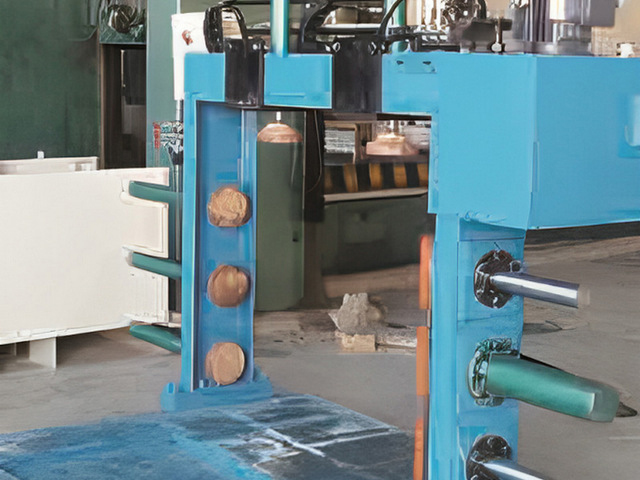

The layout and manufacturing of tooling fixtures are personalized in accordance to particular processing necessities and parameters such as the form and dimension of the workpiece. They can be in the structure of clamping jaws, clamping arms, clamping clamps, clamping beds, finding pins, aid frames, vacuum suction cups, etc.

The predominant feature of a tooling fixture is to supply correct positioning and secure clamping to make certain the right function and pleasant of workpieces at some point of manufacturing and manufacturing processes. They clamp and guide workpieces, maintaining them steady and making sure precision and consistency in machining, assembly or different operations. Fixtures can additionally make bigger manufacturing efficiency, limit assembly errors, enhance safety, and assist manipulate manufacturing costs.

Automotive assembly fixtures play an important role in the manufacturing and production process.

Their main functions include:

1. Positioning and clamping: The workpiece fixture can fix and clamp the workpiece to maintain its correct position and attitude. They provide accurate positioning, ensuring the exact location of workpieces during machining, assembly and other operations.

2. Increased productivity: By using fixtures, operators can complete machining, assembly and other production tasks more quickly and accurately. The clamps provide fixed and stable support, reducing adjustment and alignment time, thereby increasing production line efficiency.

3. Improve processing accuracy: Automotive assembly fixtures can ensure the accurate position and stability of the workpiece during processing. This helps reduce machining errors and deformations, and improves machining accuracy and dimensional consistency.

4. Control quality: Automotive assembly fixtures can ensure the position accuracy and stability of workpieces during the production process, thereby ensuring consistent product quality. They help reduce assembly errors, improve assembly quality, and help achieve quality control standards.

5. Improve safety: Work clamps can provide safe clamping and support, reducing risks during operations. They prevent workpieces from sliding, tilting or accidentally falling off, keeping operators safe.

Submitted successfully

We will contact you as soon as possible