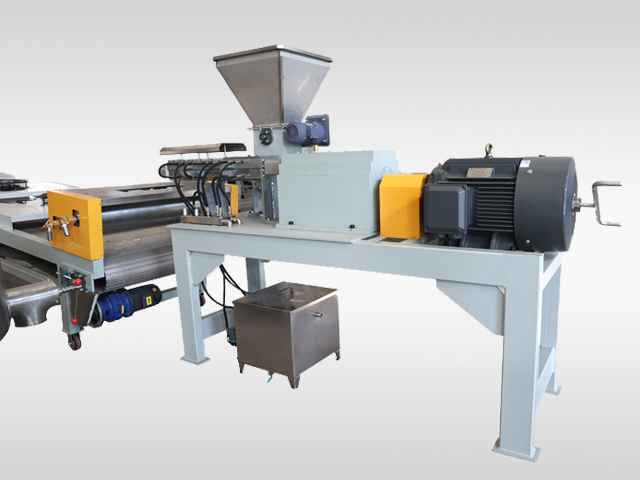

Powder Coating Extruder JCJ63

Powder coating extruder JCJ63 is appropriate for thermal microscopic uniform mixing and response in the manufacturing of thermosetting powder coatings.

The device has great performance, which is mirrored in the following aspects:

(1) Compact structure.

(2) Production effectivity 350-450kg/h (ordinary type, ornamental paint).

(3) The mixing impact is good.

(4) Strong self-cleaning capacity and no solidification tendency of saved materials.

(5) Easy to easy the machine.

(6) Cooling pace is fast.

(7) Long provider life.

Product Details Of Powder Coating Extruder JCJ63:

Earlier than the extruder begins to paintings each time, turn the motor with the crank handle to see if the rotation is straightforward and exertions-saving. In any other case, it ought to be stored on the manner temperature for 3 to 5 minutes, till the rotation is exertions-saving, and then it's far allowed to start operation.

Each time the extruder starts offevolved to paintings, the screw runs at a low speed and feeds a touch. After the fabric is extruded, gradually growth the screw pace to the fee required by using the technique.

Whilst the machine is shut down after paintings, area 1 and zone 2 have to be compelled to cool all the way down to room temperature to prevent materials from solidifying.

It's miles strictly forbidden to hold the first zone and the second one area inside the warmness upkeep nation for a long term, and to show at the device and run idling for a long time.

Product Parameters:

production capacity | 350-450kg |

Screw diameter | 63mm |

aspect ratio | 17:1 |

Number of screws | 2 |

main motor power | 37kw |

Feeding motor power | 0.75kw |

heating power | 8.4kw |

Screw revolutions | 0~540 rpm |

Submitted successfully

We will contact you as soon as possible