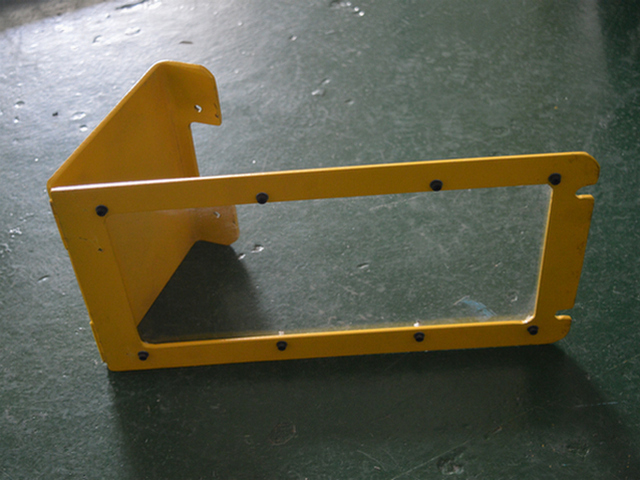

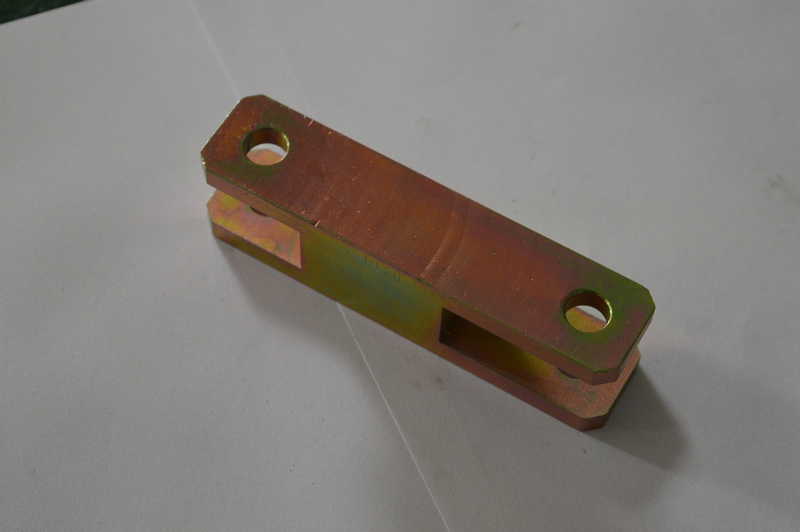

Bent Sheet Metal

Bent sheet metal processing, the bending and forming of metal sheets are carried out on the bending machine. Place the workpiece to be formed on the bending machine, use the lifting lever to lift the brake shoe, slide the workpiece to the appropriate position, and then press the bending machine. The metal is bent and formed by applying force to the bending lever on the bending machine.

Product advantages:

1. Reduce material waste.

Bent sheet metal is the process of bending metal sheets into the desired shape. It can reduce the waste of material in operations such as cutting and welding as much as possible while ensuring the quality of the workpiece. This not only reduces the cost of material procurement, but also shortens the production process and reduces the scrap rate, contributing to environmental protection.

2. Reduce pollution emissions.

Compared with traditional metal processing methods, the bent sheet metal process does not require the use of large amounts of liquid or gas, thus reducing the emissions of various chemical substances during the processing, effectively reducing environmental pollution and health hazards.

3. Optimize the production process.

The sheet metal bending process requires the use of digital equipment or computer control systems for programming and operation, which makes the production process more intelligent and efficient. The optimized production process of sheet metal bending can realize the automation of the production line, rapid transformation and employee operating comfort, thereby improving production efficiency and quality and reducing resource waste.

4. Improve product quality.

The accuracy and consistency of the workpiece can be ensured during the sheet metal bending process, allowing higher quality metal products to be produced. Compared with traditional metal processing methods, sheet metal bending can not only reduce the friction of the machine, but also avoid some heating and stretching processes that may cause damage to the material.

5. Save energy.

Sheet metal bending can complete the processing of metal plates with less energy consumption, thereby reducing the waste of energy resources. At the same time, the optimized production process of sheet metal bending can help companies reduce production costs and improve efficiency. This is also a way to save energy and resources.

Submitted successfully

We will contact you as soon as possible